Popular Pages

In December Help for Heroes commissioned a survey to better understand how long it takes Veterans to reach out for mental health support. The results suggest that on average they take four years to come forward. Help for Heroes believe this is too long. To highlight this issue, they launched the “Cut the Clock” campaign.

The delay in Veterans reaching out is partly due to believing civilian services will not understand or support them (28%)* and a fear of being treated differently by friends (25%)*.

Together, we helped 4,194 additional wounded, injured and sick individuals between August 2017 and August 2018. We know that for many, the wait was far longer than 4 years… We also know there are still thousands who are out there, struggling in silence and unable to come forward.

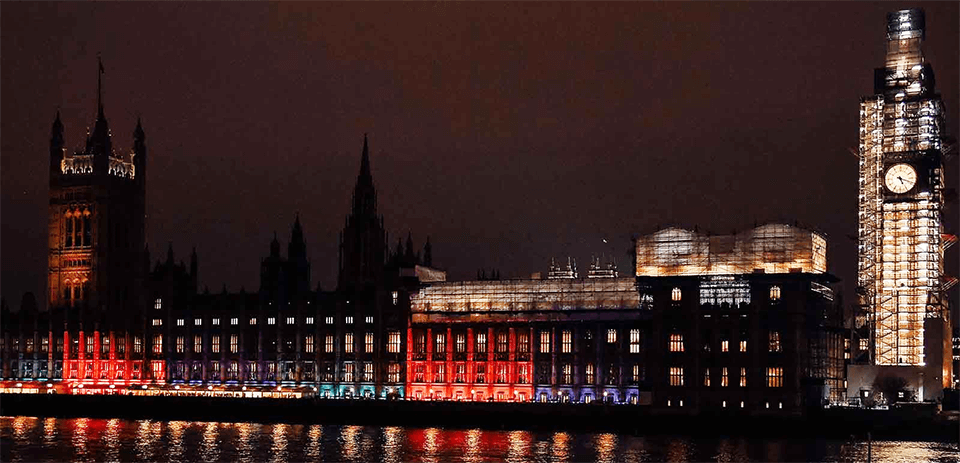

As of 21st January, Help for Heroes will be projecting the “Stigma Clock” on to various iconic buildings around the UK, starting with the Tower of London. The campaign aims to encourage supporters to get involved by sharing the message, signing up to fund-raise or donating, all of which will contributes to Help for Heroes calling time on Stigma.

We’ll be supporting the campaign throughout the year by helping spread the message, following its journey around the UK and encouraging donations to help call time on Stigma and cut the Clock! If you’d like to support the campaign in any way, just visit https://www.helpforheroes.org.uk/see-the-difference/cut-the-clock/

Around 30 potential future engineers, plus their parents came along the evening and were treated to a guided tour of the entire site including Bri-Stor Systems LCV conversion facility, Hex Signs & Graphics, Atlas Powder Coating and Alpha Manufacturing’s precision sheet metal fabrication factory.

In addition, this year’s tour included the brand-new Alpha Manufacturing offices and welfare facility which was recently completed as well a dedicated apprenticeship training facility built for next year’s apprenticeship intake.

Also on show during the evening were many of the products of apprentice team projects, such as the Soapbox Derby racers and the stunning Caterham Seven 360R, built by last years apprentices.

A mixture of Bri-Stor and Alpha engineers, current and former apprentices and Group Directors were on hand to give guided tours and answer any questions from students and parents. As usual, there were plenty of questions from engaged visitors as they were impressed by the manufacturing and engineering capabilities on site.

Many of the young visitors had already applied for either the Electro-Mechanical NVQ with Bri-Stor or Alpha’s Engineering & Manufacturing NVQ, with further applications received since the open evening.

Will Davies-Hill is Group Apprentice Manager and was delighted by the turn out:

“It was another hugely successful evening with great attendance and interest shown by those who came. The groups seemed really enthused and excited by the facilities and the course in general. For me, the most rewarding part of these evenings is to hear our current apprentices speaking really positively about their experiences and selling the programme to visitors”

Applications for both apprenticeships will remain open until 28th February, with interviews beginning in early March. Successful candidates will then begin their studies in September 2019.

Simply visit our apprenticeships page and complete a short form to register.

Having expressed an interest in a future career in engineering, the students were invited along by Bri-Stor Group apprenticeship manager Will Davies -Hill who is always happy to offer the opportunity to local students:

“We like to build strong relationships with local schools and academies and it’s probably the 3rd consecutive year that we’ve hosted Kingsmead students. We’ve also visited the school and presented our apprenticeship programme on numerous occasions. The factory tours are really useful in terms of showing young people first-hand the opportunities available within manufacturing and engineering and something we do regularly”

Many of the Kingsmead students who visited this week have expressed an interest in either an Alpha Manufacturing or Bri-Stor Systems apprenticeship and will be returning on the 23rd January for the annual apprenticeship open evening.

There are still spaces available to attend the Bri-Stor Group apprenticeship open evening and registration will remain open until the event.

Simply visit the open evening page and complete a short form to register.

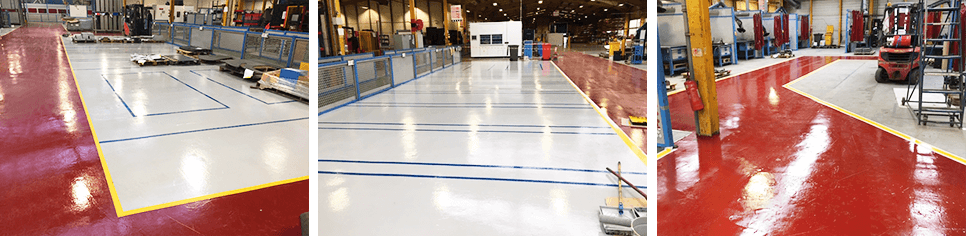

As part of the process, all working, pedestrian and storage spaces are redefined and clearly marked with designated colours. The entire factory shop floor is re painted with hard wearing industrial paints – around a 65,000 square feet area in total. The process is an important factor in maintaining standards both in terms of lean manufacturing practices and health & safety.

In addition to the paint out, work has begun on improving factory lighting through cleaning of skylights throughout the entire factory. A major undertaking, the project will be ongoing over the coming months, resulting in a much better working environment for shop floor operatives.

As in previous years, 2019 will see some major developments to the Alpha factory as work continues towards the 20/20 vision outlined back in 2015. Building work has begun on a brand-new stainless-steel processing cell, while preparations are ongoing for the installation of a Salvagnini P4 Lean panel folder, announced by the company late in 2017.

The annual open evening gives local students interested in a career in engineering the perfect opportunity to find out what an apprenticeship has to offer.

Starting at 5.30pm on 23rd Jan, the event is always well attended and gives prospective apprentices the chance to take a guided tour of both the Bri-Stor Systems and Alpha Manufacturing facilities, followed by a Q&A with expert engineers. Previous apprentices, many of whom are now full-time employees, are also on hand to share their first-hand experiences of the Group and to answer any questions.

Will Davies-Hill, Bri-Stor Group apprenticeship manager said of the event:

“The evening gives young people a chance to see the scope of the factory and meet the management team. Whilst on the guided tour they have the chance to decide which business would best suit their goals and set them on the career path they want. Overall a good evening and a vital first step towards employment for potential new apprentices”.

If you’re interested in a career in engineering and want to find out more about how an apprenticeship works, the Bri-Stor Group open evening is the perfect event for you.

Simply complete the short form below and we’ll see you on the 23rd January.

Corey Hammond and Reece Smith, who are in there first year of an engineering manufacturing apprentices at Alpha, were on hand to answer any questions that students might have.

The Cannock Chase careers fair marks the beginning of a busy period of recruitment for Alpha and the Bri-Stor Group, with a busy calendar of events, culminating in the Bri-Stor Group apprenticeship open evening on the 23rd Jan 2019.

Group apprentice manager William Davies-Hill was at the Cannock Chase College and was impressed with the young apprentices he took along.

“It’s great to see these young guys talk so confidently and positively about their experiences throughout their apprenticeships so far. It’s far more effective for young people to hear it from their peers who are currently living the apprenticeship than from myself. They do a great job whenever they represent us and it makes me proud.”

2018 was the most successful apprenticeship recruitment drive in the Bri-Stor Group’s history, with a record number of apprentices joining either the Alpha Manufacturing or Bri-Stor Systems programme. This year, the Group are looking to recruit a further 15 across the two companies.

The Bri-Stor Group apprentice open evening is open to student who have an interest in an engineering apprenticeship, along with their parents. The evening will be held at the Group ‘s Hixon site on January 23rd and will consist of a meet and greet, factory tour and Q&A sessions. If you’d like to attend, please complete our short registration form.

The new facility will provide the perfect environment for the young engineers to complete any theory-based aspects of their NVQ work, receive internal and external training and work on group projects such as the soapbox and Caterham projects. Equipped with network and internet access, computer work stations and projectors, the facility has everything needed to give Bri-Stor Group apprentices the best opportunity to learn and succeed throughout their training.

Previously, group apprentices had utilised various facilities and meeting rooms around the Bri-Stor site to complete training and coursework. The obvious logistical issues of sourcing these facilities within a busy working environment meant that a dedicated space was required. The next intake of young apprentices, due to join from the JCB academy during September will now benefit from a dedicated quiet space to learn.

Bri-Stor Systems apprentice manager William Davies-Hill commented:

“This new facility will give the apprentices a hub to conduct all non-practical elements of their studies, so any presentations, training or project work can be completed here. It’s going to be really beneficial to future apprentices in terms of their learning and development and personally I’m delighted to have the facility.”

The Bri-Stor Group apprenticeship scheme has grown form strength to strength since its inception in 2010 with a year on year increase in both applications and course completion. Today, 42 apprentices are studying toward an NVQ qualification across the group, including several higher apprentices in both Alpha Manufacturing and Bri-Stor Systems.

This latest investment is a continuation of Alpha’s long-term investment strategy which has seen installations of a STOPA storage system, TruPunch 5000 S12, TruLaser 3030 and Trubend 7000 machine take place over the past 18 months. It also comes shortly after work began to build a brand-new office and canteen facility on their 35-acre Hixon site.

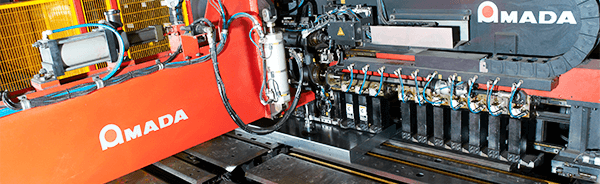

The P4 Lean will replace the outgoing Amada TBZ panel folding machine which has been in operation for 15 years and will hugely increase Alpha’s sheet metal folding capabilities. A host of additional features and systems have been specified with the P4 to maximise productivity and efficiency, including Salvagnini’s latest interactive programming suite – Streambend, which allows programmers to run a virtual simulation of the part in a 3D environment before any material is processed. Alpha will be one of the first sheet metal fabricators in UK to use this software.

Streambend offline programming software, combined with the P4’s ability to integrate with Solidworks CAD software will dramatically increase Alpha’s panel folding capacity. By moving away from manual shop floor programming to offline office-based programming, Alpha will now be able to offer a much more efficient panel folding service.

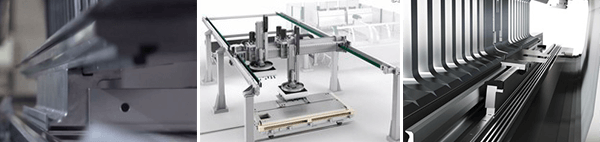

The ABA blankholder automatically changes its configuration and its length according to the dimensions of the panel to bend without any input from an operator.

The CLA tool allows the P4 to make multiple positive and negative short bends to the same part, engaging and disengaging quickly and automatically between the blank and bending blades. This function is ideal for creating upward and downward tabs.

The P tool allows for the handling of very narrow profiles and creating tubular, hidden or radiused bends. It also allows for preformed parts to be folded easily and automatically.

MAC 2.0 (Material Attitude Correction) detects any material variations by the panel bender and, if values are outside the tolerance range, automatically compensates by adjusting the blade movements.

An automated loading/ unloading carriage positions the raw sheet in the machine whilst simultaneously pushing finished parts towards the unload conveyor.

Thanks to Salvanini’s clever automated tools, the p4 is able to fold much more intricate and complex parts, where limitations to the TBZ had previously seen these types of components folded manually on press brake machines. Complex parts with details such multiple positive and negative bends, tabs or embossing have until now been manually re-positioned by an operator for each bend. The P4 however, enables all of these to be achieved in one seamless process, dramatically reducing processing time and manual handling.

As with all of Alpha’s recent investments, the P4 forms part of a long-term factory development plan which will eventually see it integrated into the STOPA storage machine. This will further automate panel folding capabilities as raw material is fed into the P4 and removed once processed without any manual handling.

“The TBZ machine had served us well but the time came to replace it and as with all of our recent investments, we looked at the bigger picture when choosing a new machine. We don’t just want a like like-for-like replacement but an upgrade which opens up new capacity and opportunities for us whilst also fitting into our overall long-term plan for the business. The P4 ticked a lot of boxes for us in terms of its capabilities and what this allows us to offer our customers.”

Installation of the Salvagnini P4 is scheduled for early 2019 and will take around 6 weeks to complete. In the meantime, Alpha’s panel bend operatives and programmers will undertake intensive training on the new machine. Programs will be created well in advance of the machine installation so that production on the P4 can begin immediately.

Alpha Manufacturing apprentices Sam Weaver & Owen Jones were last week invited to Wolverhampton University for a tour of their school of engineering and UWR Motorsport facility.

With both Owen & Sam soon to start further education in the form of Mechanical & Manufacturing Engineering and Electrical Engineering courses respectively, the visit gave them valuable insight into a wide range of advanced manufacturing techniques.

The two young engineers where given the opportunity thanks to the ongoing relationship between the Bri-Stor Group, of which Alpha are a part and the UWR team. Over the past few years the group has supported both F3 and formula student teams with graphics supplied by Hex Signs & Graphics and various vehicle components manufactured by Alpha.

The UWR programme offers young engineers a unique opportunity to combine theoretical studies with real world, hands on engineering within a competitive environment. Competing in a range of championships including the F3 cup, Formula Student Cup, AR Morgan Challenge and British Hill-climb Championship, the UWR team relies heavily on sponsorship and support from companies such as the Bri-Stor Group.

Responsibilities:

Operate Press brake machines and support the production team by assembling parts, operating machinery, punching or sawing of metal products as instructed by supervisors. Produce a variety of parts, all of which must meet the dimensional specifications of the mechanical engineered drawings.

This position may include all or some of the duties and responsibilities listed below.

Press Brake Operator Job Duties:

Press Brake Operator Skills:

Customer: A Leading UK Balcony Supplier

Sector: Construction

Product: Glazed Balconies

Quantity: 100

Duration: 5 Weeks

Project Background

This client, a leading UK balcony supplier, conducted an extensive procurement process before choosing Alpha as their chosen precision sheet metal fabrication partner for the manufacture and assembly of their products.

Having won a contract to supply and fit 100 glazed balconies to new build apartments, they placed their order with Alpha.

The project required Alpha to manufacture, assemble and store 100 unique, patent protected glazed balconies, before delivering all balconies to site in one.

Project Challenge

Initially, Alpha’s customer required a complete prototype including timber decking and glazing, with Alpha’s design team working closely with the customer initially. Once signed off, full production began with all 100 balconies required within 5 weeks of order.

The glazing element of the project was a new challenge for Alpha, having never worked with glass panes previously. Glass handling equipment was acquired and training quickly implemented.

New assembly and storage facilities were also quickly secured to accommodate the project and Alpha’s assembly teams were expanded.

Project Outcome

Alpha completed the initial prototype ahead of project commencement, working closely with the client to value engineer the design. Once the prototype was signed off, manufacturing of components began with new assembly areas set simultaneously up in preparation.

Having not produced complete balconies prior to this project, Alpha put in place several new resources to ensure the successful completion of the project.

A new dedicated assembly area was put in place, with Alpha acquiring new premises specifically for balcony build projects.

Assembly teams were up-skilled and trained in glass handling, using new lifting and handling equipment.

Both the implementation of the assembly resource and the build plan were carefully managed to ensure that all agreed deadlines were met, adhering to the delivery schedule.

What our Customer said…

“As the UK’s leading balcony specialist, we were looking to take our supply chain to the next level. I visited numerous factories across UK and Europe, following which we chose to form a partnership with Alpha. We chose them because we were very impressed with their lean set up, substantial investment in excellent equipment, and a consistent culture across all those we spoke with which was passionate about creating quality products. We are looking forward to a long partnership together.”

The all new Alpha Manufacturing website went live this week after months of design and development work to bring the company’s online presence up to date.

Following a sustained period of success and growth for the Hixon based precision sheet metal fabricator, the decision was made to refresh the company’s online presence. The previous Alpha website had served the company well since it’s launch back in 2012 and had become a useful knowledge source for designers and engineers looking for technical manufacturing information.

Having invested heavily in machinery, facilities and technology over the past 2 years, this latest investment to the website now means that Alpha’s online presence accurately reflects the progression of the company as a whole.

The new online platform retains the same level of technical manufacturing expertise as the previous site in the form of case studies, in depth FAQ’s and expert blogs but makes accessing, interacting and sharing content much easier.

Designed with the customer in mind, the site makes it as easy as possible for visitors to access relevant information and importantly, make quick enquires. Within a few clicks, visitors cand find themselves watching any one of Alpha’s various sheet metal processing machines in action, reading insightful manufacturing blog pieces or even walking around the Alpha factory via a 3D virtual tour.

Rob Eley, Alpha’s Commercial Manager, explains the reasons for the update:

“Increasingly, potential customers are finding us online and it’s important to make sure that what they find when arriving at our website accurately reflects the type of company that we are. This new site will hopefully give visitors an overview of our cutting-edge facilities and expert approach, whilst also offering some useful insight into sheet metal fabrication in general.”

All twelve 7m x 4m units have now been craned into position ready for electrical installation and plumbing works to begin. Alpha’s entire office staff including management, design, operations, sales and administration teams will be based on the second of two stories, with canteen space, toilets and changing facilities for all 100+ shop-floor staff housed on the ground floor.

As part of Alpha’s long-term growth strategy, factory shop-floor space will be maximised with further investment in new machinery planned over the coming years. In particular, the automated STOPA machine, installed in 2016 will be extended to run the entire length of the factory with all processing machines being integrated.

This means changes to the shop-floor layout, including relocation of the operations office, which currently sits at the centre of the factory. By relocating the office, valuable space is freed up for the continued development of the factory.

In addition, the new offices have been designed with collaboration, interaction and productivity in mind. Open meeting spaces, built in office kitchen facilities and even a communal balcony have been specified to encourage a positive, productive work environment. 5s principles will be implemented, with a clean desk policy and single waste management facility replacing individual under desk bins.

Paul Clews, Alpha’s Operations Director is excited by the project:

“Aside from the need to relocate the office to facilitate our plans for the factory, the benefits in terms of productivity and efficiency through creating a good work environment are clear. We try to give our employees all the necessary tools to perform to their best and our aim with the new offices was no different.”

Once electrics and plumbing are completed, an entire suite of modern office and canteen furniture will be installed before landscaping, pedestrian walkways and car parking facilities complete the project in around 6 weeks’ time. Alpha’s staff are eagerly anticipating the move and looking forward to starting work in their new space.

Sam delivers his 5S presentation to a production team.

Alpha’s commitment to developing young engineering talent through our apprenticeship programme continues to pay dividends as apprentices from the 2016 intake begin to make a real impact within the business and build solid foundations to their own careers.

As Alpha’s 2016 group of apprentices complete their official training and move into full time employment with the business, they begin their career in earnest as they start to develop individual skillsets and specialise in specific areas.

Some, for example have shown an aptitude towards programming and are set to begin RADAN training which will equip them with the skills needed to work within the office programming team. Others, such as Faisal Kahn will take on greater responsibilities within specific departments. Faisal spent time working alongside Alpha’s dedicated Robotic fold programmer on the TruBend 7000 machine and will now take on greater responsibility in this area, able to run the machine solo going forward thanks to his rapid progression.

Faisal Khan Operating The Trubend 7000 Machine

Two members of the class of 2016 will go one step further, undertaking additional education alongside their work with Alpha to achieve extra engineering qualifications which will help them further specialise in their careers. Owen Jones will be attending Stafford College as of August this year, where he will be studying towards a level 3 NVQ in electrical engineering over 3 years. During his apprenticeship with Alpha, Owen has developed impressively, showing particular potential in electrical engineering having worked alongside Alpha’s maintenance manager for the past 6 months in tending to Alpha’s machinery and systems repairs.

“I’ve really enjoyed working on all the different machinery around the factory and learning how different things work. Once I finish my college course I want to take different courses specific to each machine so I know them inside and out. My ultimate goal is to become an Alpha maintenance manager and be responsible for keeping the factory working.”

Sam Weaver will also be undertaking further education at Derby University, where he will take a 3-year foundation degree in mechanical and manufacturing engineering which will see him progress onto a masters degree in manufacturing and production. Sam has already begun to make an important contribution to Alpha’s operations by creating a 5S implementation plan which he’s delivering to all departments through a series of 1-hour training sessions. Once training is complete, Sam will be responsible for ensuring that 5S disciplines are implemented and adhered to around the factory shopfloor regularly, with the aim of improving organisation and ultimately productivity.

“The training has been really well received so far and people seem enthusiastic to improve their organisation and efficiency. I’m looking forward to seeing the work I’m doing at the moment start to take effect within the company over the next few months. Once I’ve completed all the training sessions, there’ll be a series of shutdown days where we can really start to implement the changes.”

The impressive progression of these Alpha apprentices is further vindication of the company’s commitment to training and development, with young engineers already showing the promise that they can contribute positively to the business. With the 2018 intake just recently beginning the theory portion of their apprenticeships with the JCB academy, Alpha are already anticipating another fresh influx of raw engineering talent ready to be moulded when they begin their practical training at the manufacturing facility.