Accurate laser cutting technologies

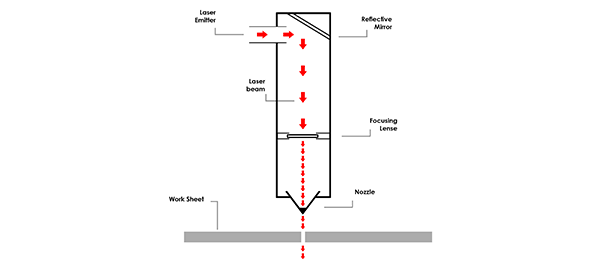

Laser cutting is a precise method of cutting a design from a given material using a CAD file to guide it. This thermal cutting process uses two forms of laser sources: fibre laser and CO2 laser. The fibre laser is the most innovative laser cutting technology currently on the market.