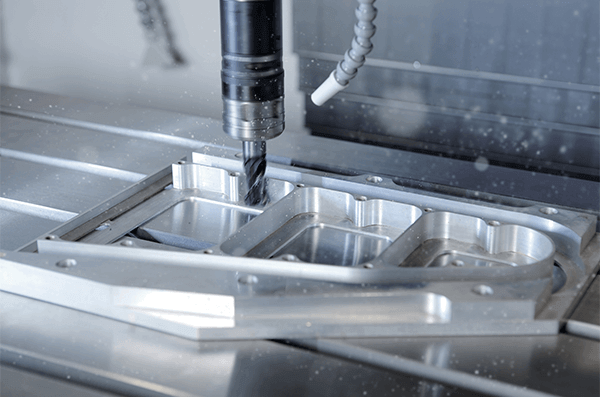

Alpha Manufacturing’s state of the art 3 axis machining centre allows us to machine ultra-complex profiles and shapes in a variety of materials with unbeatable accuracy. To achieve this, we use:

Popular Pages

Alpha Manufacturing’s state of the art 3 axis machining centre allows us to machine ultra-complex profiles and shapes in a variety of materials with unbeatable accuracy. To achieve this, we use:

The VTC-300 CII is a highly versatile vertical machining centre with a large 2000 mm table cross dimension and high-speed rapid traverse of up to 36 m/min and features a powerful 40 Taper spindle, full travelling column design, and a table centre partition.

Productivity and efficiency are greatly improved as the machine work envelope is separated into 2 work areas. This allows the machine to be in cycle, in one work area, while a part is being set up in the other work area. Fast rapid traverse rates also enable the Mazak VTC-300CII to reduce non-cut times.

Offering the ability to streamline projects and ultimately reduce production costs, Alpha Manufacturing’s UK-based CNC machining facilities cater to a range of project scopes. Investing in industry-leading technology allows Alpha to offer versatility, accuracy and efficiency from project start to finish. Find out more or upload a technical drawing today.

CNC Machining is the process of removing material from a solid piece by either drilling, turning or milling until only a desired shape remains. The workpiece is manipulated on either 3 or 5 axis as the tools subtract material according to a pre-determined program. Complex precision shapes can be created from metal by using CNC machining.

An overview of Machining facilities at Alpha Manufacturing:

Metal turning is the process of removing material from a rotating part using a single blade to create a cylindrical part. As the piece is rotated, the cutting tool is moved in a direction parallel to the axis of the workpiece.

A rotating tool with either two or four cutting edges is forced down into the workpiece to create a hole.

A rotating tool with many edges is moved in various directions along the face of the workpiece to create a new plane or face.

There are numerous turning, drilling and milling machines available offering varying degrees of flexibility.

At Alpha Manufacturing our machining department consists of:

The VTC Machine is a highly versatile 3 axis machining centre which can machine more complex profiles at a fast rate thanks to sophisticated features.

Online programming for machining involves using a design drawing or model and manually working out a machine path using x, y and z axis. This is often a complex and drawn out process which requires experience and expertise.

At Alpha Manufacturing, we recently purchased a new offline programming software called “One CNC” which allows a 3D model to be imported and manipulated on screen. It allows the operator to easily select a surface and apply a process to it. The software will then calculate all of the angles and mathematics which the operator would previously have done.

We currently operate both online and offline forms of programming for machining, depending on the complexity of the parts.

At Alpha Manufacturing, we predominantly machine:

An example of 3 axis machining:

The primary limitation in machining is the manipulation of the workpiece and accessibility of the tools at various angles. Depending on the complexity of the profile, the machine head may need to access the workpiece at multiple angles or Axis.

At Alpha Manufacturing, we currently operate 3 axis and 4 axis machines which offer enough flexibility for the majority of products that we produce. 5 axis machines are available which allow the machine to access the workpiece at more angles along 5 different axis.

If you have a question regarding CNC Machining or any other sheet metal processes, please get in touch

We work with businesses in a wide variety of sectors with capabilities to offer short and long runs of metal products.