Alpha Manufacturing is able to offer a variety of different manual metal folding and CNC folding solutions, which allows us to select the most suitable and efficient method to meet the individual needs of each customer.

What is metal folding?

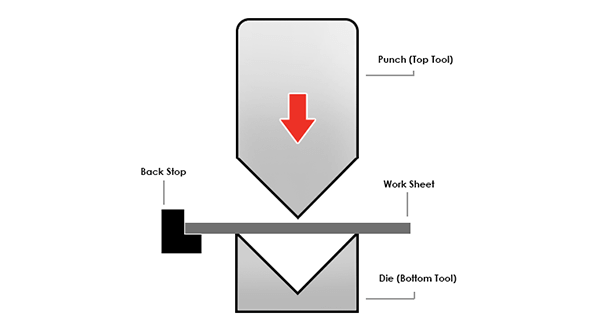

Metal folding is the process that gives the metal product its shape. A machine is used to bend (or fold) the metal in order for it to reach its intended form. The benefits of using this robust and efficient machine are that it can fold small intricacies and create a variety of shapes for many day-to-day products.

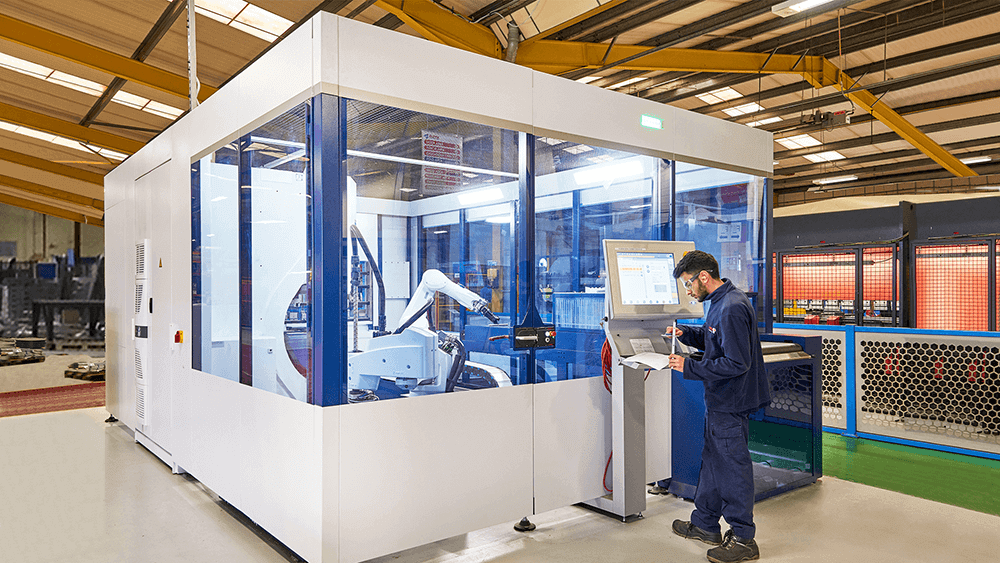

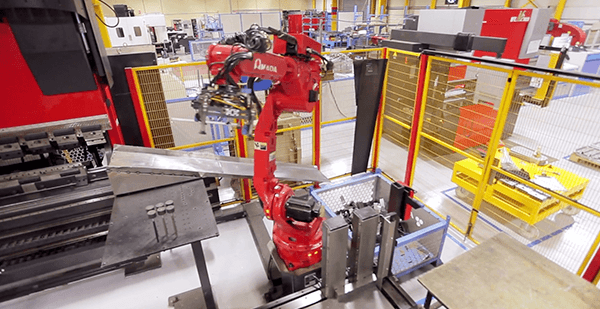

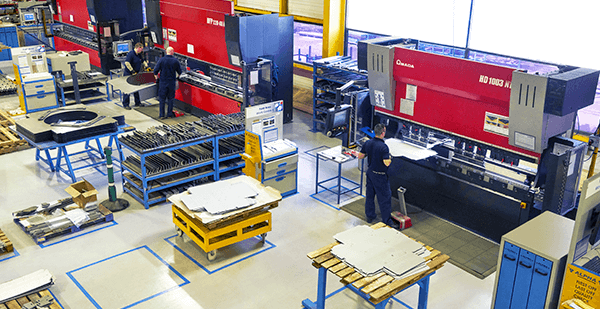

Our folding department consists of manual press brakes, automated panel folding machinery and automated robotic folders, which means we’re able to match individual customer requirements to the most suitable metal folding solution.

Our commitment to continual investment means that we now have the following folding facilities at our disposal.