What is sheet metal folding?

Metal folding or forming is simply the process of applying one or bends to a sheet of metal by securing the sheet at a certain point and applying enough pressure to fold the metal.

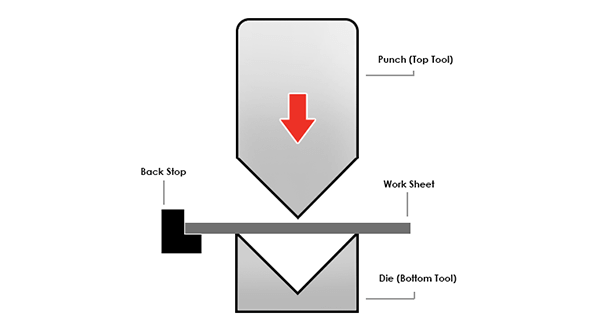

The angle of the bend is usually determined by the shape of the top or bottom tool (usually a “V” shape) and also the pressure applied.

A diagram of a pressbrake punch and die:

What machinery is used to fold sheet metal?

This depends on a number of variables such as material, size, quantity and complexity of the parts required. At Alpha Manufacturing, we have a range of folding option, including press brakes, automated panel folding and robotic.

What is a manual press brake?

The traditional and most common method of folding is to use a press brake machine. We have seven manual Amada press brakes which form bends by clamping the metal sheet between a punch and die (top tool and bottom tool. An operator will feed in the sheet to a pre-set back stop and hold the material in place whilst the press brake applies the bend.

What is an automated panel bending machine?

More advanced machinery is available for automated folding which involves less operator involvement. We use a TBZ panel folding machine which works differently from a press brake in that it doesn’t use a v tool. Instead, it clamps the work piece in place before applying upwards or downwards pressure depending on the direction of the bend.

The TBZ Panel bending machine does not require an operator to feed in the material. This machine is programmed offline and will feed in its own material, output a finished part and also select its own tools based on the pre-determined programming.

What is a Robotic bend cell?

Even further advanced folding machinery utilises robotics to fully automate the folding process. We operate an Amada Astro Robot folder which has a robotic arm which picks up material, feeds it into the fold tool and applies the pressure.

Our latest investment in fold machinery – the TruBend Cell 7000 takes this one stage further. Fully automated, it has a robotic arm which selects material, scans it to ensure that it is the correct spec, can apply multiple bends, then scan the finished part to check the dimensions are correct and then place the finished parts on a conveyor to be stored.

These automated robotic folding machines are the most efficient and accurate available today. They are most suited to high volume, repeat manufacture, particularly of smaller products.

What is the sheet metal folding process?

The first stage of the folding process is for our design team and programmers to agree on the best method of folding the product using their extensive knowledge. This will determine the fold machinery that is used and the process that will be applied.

Our programming department will then write the appropriate programmes for the machine selected. These will either be a program for a manual operator to follow or for one of the automated machines to run. Programmers will consider factors such as material utilisation and run time of the job to fit the job into the manufacturing schedule.

Depending on the complexity of the part, folding may or may not be the first process for the metal sheet. It will be scheduled and arrive with the fold department at a pre-determined time before an operator will oversee the processing of the part on the specified machine. Once folded and checked, the part will then be moved, either to the next department for further processing, or to despatch for shipping.

What is a bend radius?

The bend radius when folding sheet metal refers to the inside radius of the bend and there are many factors to consider to achieve the correct bend radius in sheet metal.

Depending on the material, thickness and density, there will be a degree of “spring back” which must be accounted for. To counter act this the sheet must be “over bent” to achieve the correct internal radius after spring back.

What materials can be CNC Folded?

We can fold various materials including:

- Mild steel

- Coated steels

- Stainless steel

- Aluminium

- Alloys up to 4100mm in length and 2.3mm thickness.

If you have a question regarding folding or any other sheet metal processes, please get in touch