Our plant is fully automated and employs industry leading pre-treatment process OXSILAN®.

Popular Pages

Our plant is fully automated and employs industry leading pre-treatment process OXSILAN®.

OXSILAN® is a new metal pre-treatment technology that is free from hazardous chemicals and provides superior corrosion resistance for a wide range of metal substrates.

OXSILAN® replaces traditional iron and zinc phosphate products. The products provide a superior ecological profile. OXSILAN® is suitable for metal surface treatment, e.g. cold rolled steel, aluminium, zinc coated steels, as well as multi-metal applications.

Stage 1: Is a highly Alkaline cleaner for steel alloys and zinc-coated steels

Stage 2: Cold rinsing from the main water supply.

Stage 3: Rinsing with Demineralised water

Stage 4: Oxsilan 9810 is a silane-based multi-purpose liquid pre-paint treatment

Stage 5: Single ring rinsing with Demineralised water

Powder coating is the process of applying a paint finish to a metal product using a dry powder and an electrostatic charge. The positively charged polymer powder is initially attracted to the grounded material by electrostatic charge before heat is then applied to cure the powder and create a finished covering.

As there is no liquid element to the powder coating process, there is no solvent needed, reducing hazardous chemical production. The electro-static curing process also means that there is no sagging or running, allowing for much thicker paint coats.

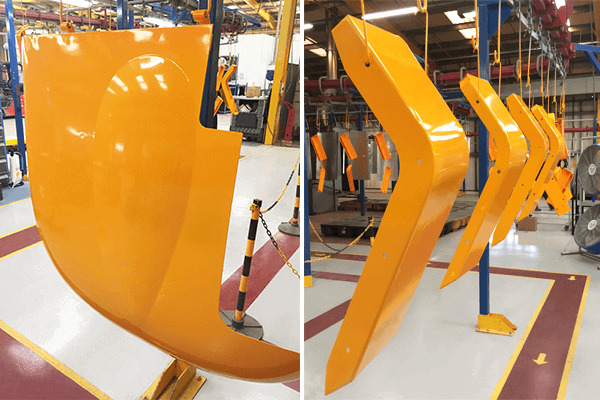

Examples of freshly powder coated agricultural machinery body parts:

The most efficient method of powder in high volumes in to use a complete paint line. This is motorized track to which unfinished parts are attached usually by hanging. The track runs through each stage of the powder coating process until the finished parts are removed at the end of the line.

As the paint track moves, the hung parts pass through various specific stages which ensure the final quality of the paint finish:

A highly Alkaline cleaner is applied to the parts which removes any manufacturing residue and other dirt, the parts are then rinsed firstly with mains water and then with demineralised water. A saline based liquid pre-treatment called Oxsilan 9810 is then applied which relies on chemical bonding to protect against corrosion. Finally, the parts are rinsed with demineralised water once more.

The pre-treated parts are then passed through an oven at around 180 degrees to dry them ready for the epoxy paint powder.

The track now carries the grounded parts through an automated spray booth where electrostatic spray guns begin to apply the charged powder to the parts. The parts then pass through another area where manual electrostatic spray gun operators cover any difficult to reach areas.

Finally, the coated parts will pass through a gas-fired tunnel oven to cure the powder. The required temperature of the oven will depend on the type of powder applied and at the critical temperature, the powder will begin to flow and then bond. This bonding creates the final smooth finish of the paint.

Example of Alpha Manufacturing’s powder coating plant:

Powder coating is available in any colour including metallic finishes such as gold or silver. At Alpha Manufacturing, we offer a standard range of colours and all else are available on request.

Other finishes such as plating or EPD (electrophoretic dip coating) are also available.

Generally, powder coated finishes are more resistant to chipping, scratching, fading or wearing than other paint finishes. This is due to the fact that the coat is thicker and also because the chemical bonding which occurs during stoving is so robust.

At Alpha Manufacturing, we apply a pre-treatment called Oxylan 9810 which allows us to guarantee a 1000-hour salt spray protection. This is ideal for products used in harsher outdoor environments.

If you have a question regarding Powder Coating or any other sheet metal processes, please get in touch

We work with businesses in a wide variety of sectors with capabilities to offer short and long runs of metal products.