What is sheet metal Laser Cutting?

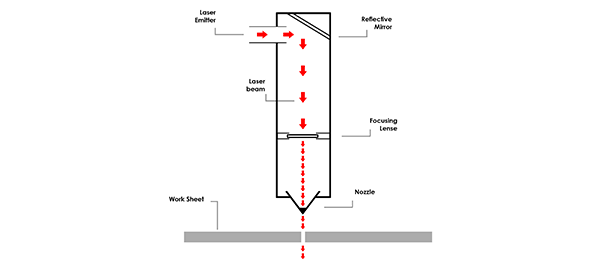

Laser cutting is an extremely accurate method of cutting precise shapes from a workpiece (usually sheet metal). It works by focusing a high-powered beam at the work piece, which in turn will melt or even vaporise the material.

The laser beam then follows a pre-determined path to cut out the parts, melting the material as it goes, this allows for very complex shapes to be created quickly and accurately. Parts are then removed from the sheet metal skeleton by the operator. This is known as “breaking out”.

What machinery is used to laser cut sheet metal?

There are two primary types of laser cutting machines; Co2 and Fibre Lasers which operate slightly differently and have individual characteristics. At Alpha Manufacturing, we currently operate two Fibre Lasers and one C02 machine.

An example of a Trumpf TruLaser Fiber Laser machine:

How do Co2 Lasers work?

Co2 Lasers are the most commonly used laser cutting machines. They use a carbon dioxide gas mixture which is charged using a high intensity electronic current. The C02 Laser is highly efficient and accurate, with a wavelength of around 10.6 micrometres it is most useful for laser cutting non-metallic materials such as wood or plastics.

What is the Fibre laser cutting process?

A fibre laser is what’s known as a “solid state” machine. It generates a highly focused beam using a “seed laser” which is then amplified many time over using glass fibres. This creates a small diameter laser beam which is up to 100 times more intense than a C02 beam. This makes a fibre laser much more energy efficient than the Co2 alternative.

How are parts programmed for laser cutting?

Programming parts to be laser cut is much like programming parts for punching. The programming department will receive a nesting list from planning, this will outline the laser jobs for that day.

Programming will then work on this list, producing what is called a “nest” of parts on a sheet. Obviously, it is beneficial in terms of cost and efficiency to fit as many parts on one sheet as possible, so the programmers will nest as many parts as closely together as possible.To achieve this, the programming department use a piece of software called Radan.

The programmer will receive a part model from the design department and import this into the Radan “multi-part nester”. Using this, the programmer can lay out multiple parts onto the sheet; this is referred to as “nesting”.

Finally, the programming department will output the program in the form of a “block file” which the Laser machine operator will input into the machine and produce the parts as specified in the program.

What materials can be laser cut?

The majority of the laser cutting we do here at Alpha Manufacturing is from sheet metal. We can laser cut:

- Mild steel up to 25mm

- Stainless Steel up to 20mm

- Aluminium up to 12mm in thickness

However, metal is not the only material that can be laser cut and we do also process various woods and plastics.

What are the limitations of Laser Cutting?

- Often, a similar outcome can be achieved by either Punching or Laser cutting and there are factors to consider when deciding which process to use.

- Laser cutting is generally a slower process than punching as a laser needs a “lead in” before cutting a complete shape. This means that the laser will need to penetrate the material at a point before moving around a pattern to cut out a shape. A punch however will need only one “hit” to remove the shape from the material before quickly moving on to the next hit.

- Another consideration specific to Alpha Manufacturing when considering Laser or Punch is that our Punch machines have fully automated load/ unload facilities which mean that they can run 24/7 “lights out”.

- A tool called a sheet master will load blank sheets onto the punch bed, the punch will manipulate and punch the sheet before the sheet master removes the finished parts.

Our lasers currently do not have the facility to remove finished parts, meaning that an operator is needed to oversee the job whilst running.

If you have a question regarding Laser Cutting or any other sheet metal processes, please get in touch