Popular Pages

Way back in February 2020, Alpha Production Engineer Gemma committed to learning how to ride the Unicycle from scratch, before completing a 600-meter circuit through the Alpha Manufacturing factory. She had been due to complete the challenge in May and having put in hours and hours of practice, had nearly mastered it by Early April.

Unfortunately, the COVID-19 outbreak and subsequent UK lock-down meant that the challenge had to be put on hold. However, Gemma hasn’t lost her determination to complete the challenge and raise some much-needed funds for Katharine House. The Stafford based Hospice are one of many UK charity organisations heavily affected by the pandemic as lock-down and social distancing severely hindered planned fundraising events.

Research from the Institute of Fundraising earlier in the year found that one in four UK charities have seen their finances affected by the virus with projected losses of 48% to voluntary income and a third wiped off from their total income. Government grants have been crucial in helping many charities to survive and continue to offer much needed help to the most vulnerable in society.

For this reason, Gemma is committed to completing her challenge and doing her bit help Katharine House to continue their great work locally, offering holistic care and support for people with advanced life-limited conditions. The challenge will now take place at the end of September, giving Gemma a few more weeks to perfect her technique.

Here’s Gemma’s latest progress video, filmed this week after 3 months without practice:

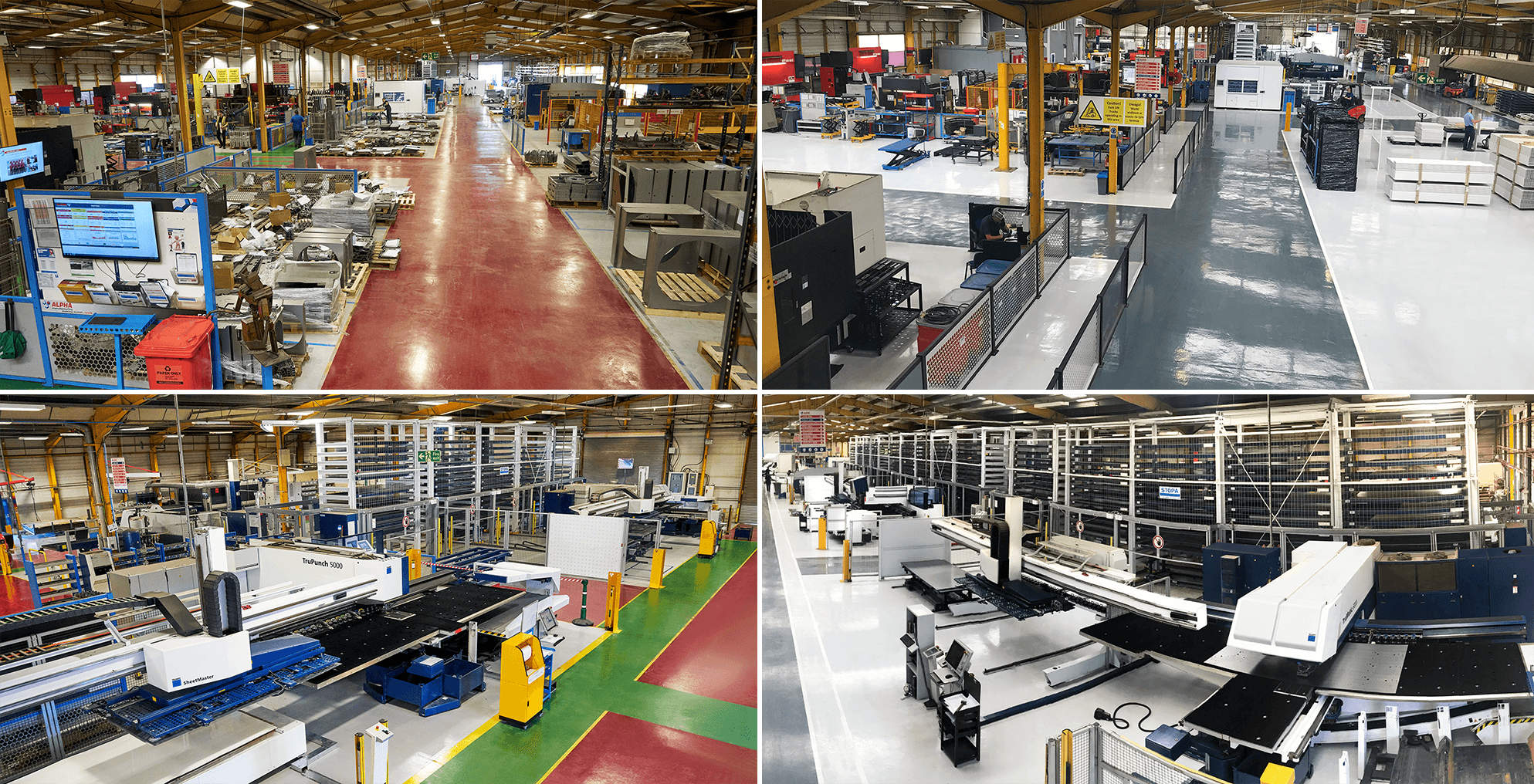

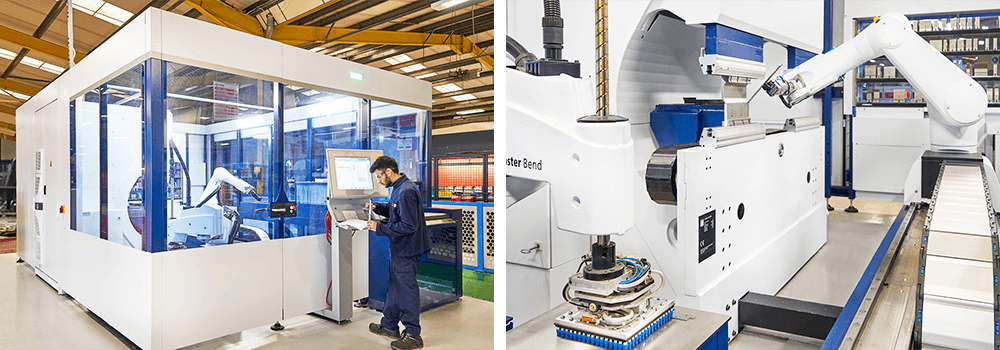

The images to left, taken after a factory paint out back in 2017 show some of the early steps of the journey, with the original installation of the automated STOPA Storage System at the far end of the factory. Closer to, the TruBend Cell 7000 automated folder can be seen in the middle of the factory, not long after its installation. These were purchased as the first stages of an ambitious 5-year investment plan which has bought the company to today’s highly organised, efficient and automated set up.

The most notable difference between the shots (aside from the colour scheme) is the amount of WIP (Work in progress) around the shop floor, with pallets of raw material and part processed items stored on pallets or in racking either side of the main gangway. At the time, these would have been manually labelled, picked by operators and transported by forklift between machines for processing. Once processed, they would then be re-labelled and moved again, ready for the next process.

The images on the right, taken after the most recent paint out, shows how far the company has come both in terms of further investment and improving factory flow. The STOPA system now extends the majority of the factory following further investment in new bays. It is now integrated into every department of the factory including laser cutting, punching and folding.

All of the WIP which was previously stored on pallets has been moved into the STOPA system as well as strategically positioned automated tower storage systems. The STOPA has been central to Alpha’s plans due to its automation of stock storage and management, part delivery and restorage of items. At the touch of a button, any operator can call for any raw material or part processed item to be delivered to any of the strategically placed delivery points around the factory. This dramatically reduces the amount of manual handling and transporting of items, increasing efficiency and improving stock management.

Neal Lafford, Alpha Operations Manager explains the impact of the system on Alpha’s operations:

“At 62 metres in length, we now have one of the biggest STOPA installs in the UK, with over 200 pallet spaces, allowing for over 600 tonnes of raw material or parts to be stored. The biggest benefit to us and in turn our customers, is the point of use part delivery, which massively reduces our need for manual storage and part movement, increasing our efficiency and reliability.”

The extra space around the shop floor allowed by the STOPA install has been maximised, with organised, designated production areas creating a logical and efficient flow of people and parts around the factory. The latest factory paint-out was designed to further enhance this with a new, simple and modern colour scheme to reflect its state of the art technology.

These protective screens have been produced for a leading internal screening supplier who requested Alpha’s support in order to keep up with the extraordinary increase in demand for their product bought about by the pandemic.

Alpha quickly set up an assembly line to produce the screens at a rate of 300 per week. To date, 750 have been manufactured, assembled and delivered to the customer, with a further 300 currently in production.

The screens will be used primarily within retail or office environments to create safe socially distanced spaces or to segregate areas of high footfall. Consisting of a plastic box section frame held upright by metal feet, PVC inserts and clear poly-carbonate top section, they offer a simple, lightweight, hygienic solution.

Demand for these type of products remains high as businesses from all sectors across the UK focus on implementing social distancing measures. Alpha have responded to requests for a wide range of COVID-19 prevention products including commercial vehicle partition screens, hand sanitising units and these internal screens.

Having joined the company back in 2000 as a programmer, Ben quickly rose into management and has since been involved in various areas of the business. Becoming Programming Manager shortly after joining, Ben then moved in a new role for Alpha as New Product Introduction Manager in 2018. He has also acted as Production Manager on various short-term production projects.

Ben now takes charge of one of the most important departments within Alpha – Quality, where his diverse experience and understanding of sheet metal fabrication processes, gathered over twenty years, will prove vital. Quality has always been central to Alpha’s service and customers are accustomed to industry leading standards, which Ben will be responsible for maintaining. Heading up the Quality Department he will oversee the daily management of Alpha’s Quality Engineers and Inspectors, as well as ensuring Alpha maintain ISO9001 accreditation, with strong process control and performance analysis to ensure total quality management for Alpha’s customers.

Ben aims to bring his own unique style to the role, with excellent man management and communication key to his approach. This partnered with a wealth of sheet metal fabrication knowledge and keen eye for detail, combined with a strict adherence to process and systems will aid Ben in maintaining the standards across the entire quality team.

“Quality Manager is a huge role here at Alpha with a lot of responsibility. Quality is vital for us as a business, we’re judged ultimately on the quality of our products, efficiency of service and reliability. If we fail in quality, we fail as a business because customers rely on us to be consistent and trustworthy, which we always have been. I want my team to build on the great work done here previously and maintain the levels, whilst constantly looking for opportunities for further improvements in processes and efficiencies.”

Now in his twentieth year at Alpha, Ben joins a growing group of Alpha veterans with fifteen-plus years at the company, many of whom have risen into management leadership roles as the company has grown. Earlier in the year, Robin Eley was announced as Commercial Director after sixteen years with the company, while Paul Clews had previously become Managing Director after nine years at Alpha. This latest promotion for Ben once again highlights Alpha’s commitment to recognising and developing talent, rewarding individual’s hard work, and pushing the company forward as a result.

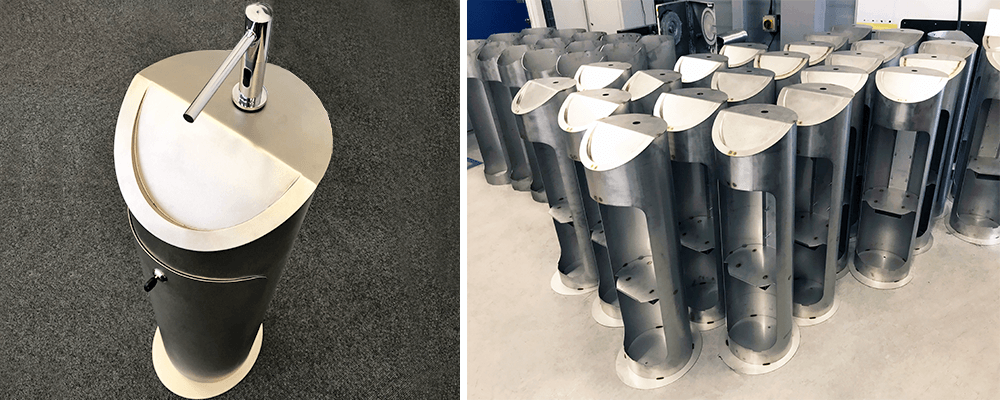

The units were required to help combat the ongoing COVID-19 crisis and have been designed specifically for higher specification environments such car showrooms or retail environments. The customer required a durable, yet aesthetic product which would fit well within a sleek setting.

For this reason, the units were manufactured by Alpha’s dedicated stainless-steel department, in a sterile environment, from grade 304 stainless steel before being bead blasted to a high-quality matte finish. The completed unit will be fitted with motion sensitive sanitizer dispenser for contactless use, making them as hygienic as possible for the user.

An initial 100 units have been manufactured, with potential for more, dependent on demand from the retail sector. As COVID-19 prevention becomes part of the “new normal” many businesses are looking for solutions which not only address the issue but can actually enhance the customer experience. Increasingly, companies are realizing that a stylish, well designed hygiene station can add much more in this respect than randomly placed santizer bottles at the door, for example.

This latest project follows an influx of orders for sanitizing and social distancing products form Alpha as a result of the Coronavirus pandemic. These include commercial vehicle interior protective screens, queuing screens and one huge order of 3500 hand sanitizing units for the leisure & hospitality sector ahead of the recent reopening of pubs and restaurants.

The majority of Alpha’s workforce have now returned to their positions, with the remaining few still furloughed due to return in the coming weeks. The Alpha factory never completely stopped production throughout the entire lock-down period, due to demand from customers involved in supporting key workers or directly supplying the NHS. A skeleton crew was deployed to ensure supply to these key sectors remained uninterrupted. As many of Alphas regular customers have begun to return to their operations and demand has risen, the workforce has been recalled gradually and now stands at around 80% capacity.

New Normal

During the lock-down, much work was done to ensure the safe return of all employees when the time was right, as the company grappled with ever evolving guidelines. The result today is a host of social distancing measures, new S.O.P’s and processes which are designed to safeguard all employees and visitors to the Alpha facility. These include mandatory wearing of face masks in and around the factory, the implementation of one-way systems in high traffic areas, social distancing messaging in all areas and numerous hygiene stations in and around the premises.

Constant communication from the company both during the lock-down and on return to work, reassured employees that every possible measure had been taken to ensure their safety. Now, procedures that had seemed alien at first have indeed become the “new normal”

The Way Forward

Unlike many unfortunate UK businesses that were blind-sided by the crisis, Alpha are in the enviable position of being financially robust enough to weather the storm and to even come back stronger. With no debts leveraged against the business, no mortgaged properties and years of shrewd accounting to fall back on, Alpha have been able to be agile and carefully navigate through the most turbulent of times.

Thanks to this, the current outlook for Alpha is much brighter than that of many other businesses. Even with the most pessimistic forecasting, there is a definite steady route back to business as usual. This should be a reassurance to current and potential customers reliant on a consistent, quality sheet metal fabrication service.

A New Plan

At the point that the world ground to a halt, Alpha were on the final straight, approaching the finishing line of an ambitious five-year investment strategy. Work had begun on the final machinery installation – an extension to the existing automated STOPA storage system. Despite the obvious hurdles to overcome, this installation was completed and is now the proud centre piece of Alpha’s shop-floor, which has also had a dramatic re-vamp in recent weeks.

Alpha’s facilities are now unrecognisable from the setup of 2015 when the investment plan was announced. The goal of creating an industry leading state of the art automated sheet metal production facility has been achieved, despite this years’ events.

As the company moves forward from the recent crisis, a new strategic plan is being formulated to consolidate Alpha’s current position and build from its solid foundations, ensuring its ability to weather any future storms as confidently as it has 2020.

Rob: We have definitely seen an increase in demand for fully assembled finished products to fine tolerances and finishes. Many of these have been modular solutions designed by our customers which reduce installation or assembly by their end-user customers.

This allows our customers to offer a complete all in one solution, which seems to be an increasing trend, particularly in the construction sector. By offering a pre-assembled modular solution through offsite manufacturing, the need for additional trades such as plumbers or electricians on site is reduced, which in turn, results in cost savings for the end-user.

Rob: Alpha takes a project basis approach to new clients. We can offer the entire sheet metal fabrication service but if something might be slightly outside of our capabilities, or if it is new to us, we will assess whether it would be viable for us and the customer to undertake the work. We’re not shy about investing in and developing new processes where required.

Alpha’s traditional business model depends on high volume and repeat requirements of products. Offsite manufacturing demands more tailored solutions, so we have adapted to become more flexible. We have done this for various new customers in recent times, which has seen our facilities evolve and our business enter new markets as a result. This flexible approach allows us to be open-minded when considering new business.

Rob: Alpha is able to offer the entire sheet metal fabrication solution. All processes are carried out on our premises, reducing cost in outsourcing and in turn, the transport required. We have the skills, equipment and engineering knowledge to take a project from design, all the way through to final assembly and finishing.

In addition, our drive towards factory automation further reduces cost for the customer as we are able to reduce waste and cost throughout processing. Value engineering is also a vital part of what we offer.

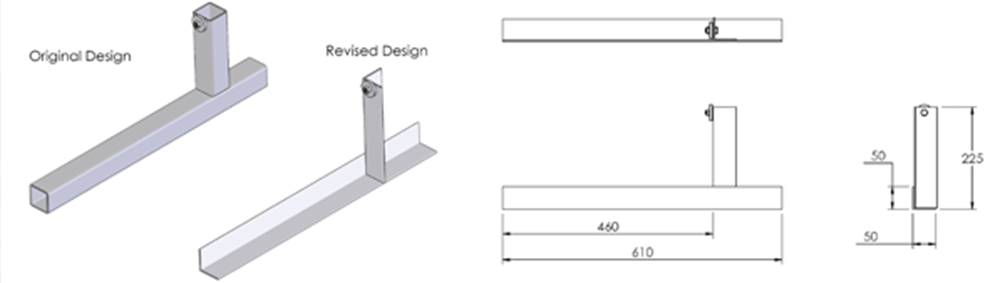

What is the benefit of carrying out value engineering before manufacture?

Rob: Value engineering is crucial for our customers in reducing the cost of manufacture. We can suggest alterations to a part or the assembly process to reduce material usage or to remove unnecessary processing time. Where possible, we will suggest new processes which are faster or less expensive to achieve the same end result. This gives our customers the peace of mind that they are getting the best value for money in their manufactured products.

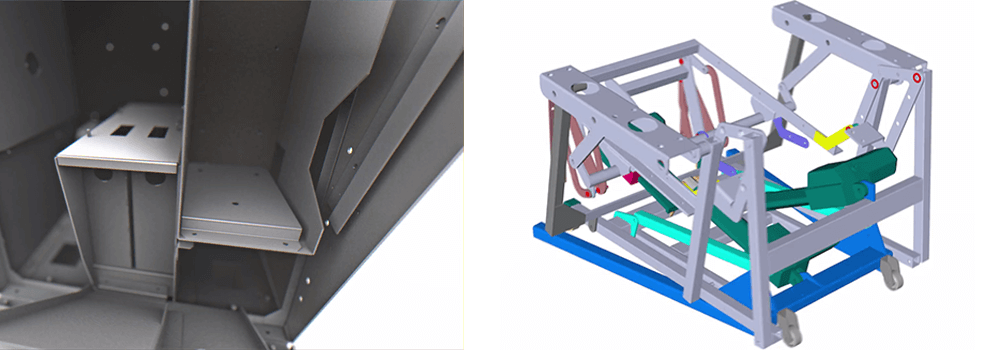

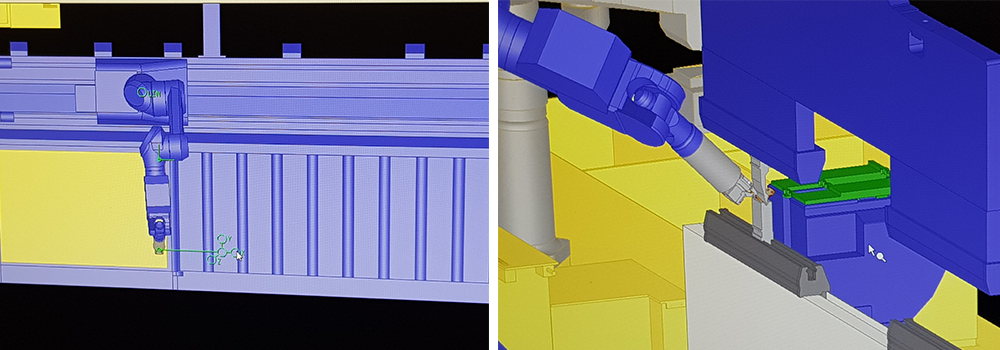

Rob: Alpha has a dedicated design team who will work with customers from the outset to refine an existing design. This allows us to design for manufacture, making sure that the constituent part or assembly is best optimised for our manufacturing procedure by using CAM systems.

We can reduce or completely remove the need for some processes by redesigning or adjusting parts in this way. All parts can be fully modelled in 3D CAD software to guarantee their dimensional accuracy. Where many components are put together into an assembly, CAD software allows designers to simulate the assembly and ensure that the final manufactured parts fit together as designed.

Rob: All of Alpha’s customers will have specified tolerances for the parts that they require, of varying accuracy. Some sectors, such as automotive or aerospace, will have very fine tolerances as their parts are often high performance or safety-critical, whereas other customers don’t require such stringent tolerances. Where many sub-components are manufactured to create one larger final assembly, accuracy in all components is crucial to ensure that the final product fits together correctly.

Rob: Alpha will always assess this on a project basis and have taken on assembly projects much bigger than anything handled previously. However, we would potentially become limited by storage space without having to acquire new premises. Also, maneuvering large components or assemblies would become an issue where heavy-duty lifting equipment is required.

Rob: Alpha works on projects from a huge range of sectors. Where assembly is concerned, our most recent projects have come from the construction sector where customers have modular solutions designed to fit straight into new builds. These are complex in the manufacturing and assembly stage, which in turn reduces the complexity and ultimately cost, at the installation stage.

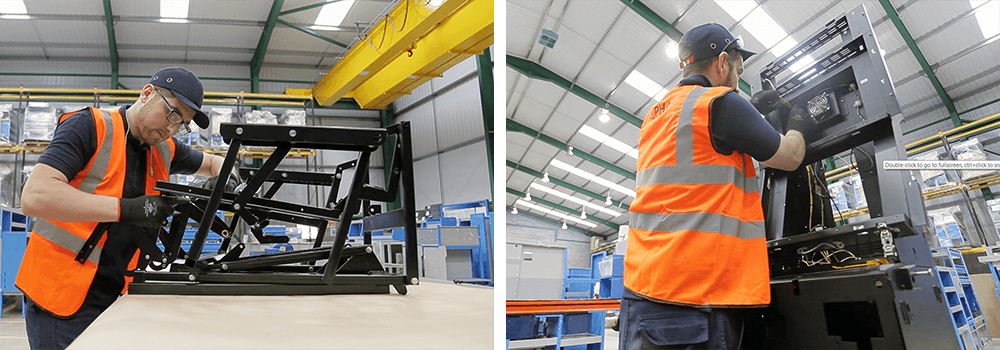

Rob: Alpha was approached by a supplier of interactive touch screen gaming machines who required a large volume of finished products delivering to high street betting shops, within a short timeframe. Alpha quickly upscaled the assembly teams with new staff and created a dedicated assembly area including several parallel production lines. Once complete, all machines were delivered to the end-user.

Rob: Alpha measures its performance on quality metrics which is a key factor for any customer looking for a sheet metal fabricator. Rejected or faulty parts can disrupt supply for customers if they have to be reworked or re-made.

Quality is crucial in Alpha’s reputation and ability to win new business. In terms of assembled products, many of the current portfolio are supplied directly to end-users in e ither residential, commercial or retail environments where a high finish standard is expected.

Despite the current uncertain climate surrounding the COVID-19 pandemic, the Bri-Stor Group apprenticeship programme continues as usual, with the new starters joining during September. This underscores both Alpha and Bri-Stor’s long term commitment to developing young talent and investing in the future, despite the short term turbulence being experienced across all industries.

Having worked hard to pass the rigorous interview process, these 12 young engineers were selected over one hundred and fifty other potential candidates. As of September, they will begin one year of studying at JCB Academy four days a week with one day per week with their companies. Following this first twelve months, they will switch to four days with their respective companies and one at the academy for another twenty four months.

The JCB academy have been training partners of the Bri-Stor Group for the past five years, providing the ideal setting to nurture local young engineering talent. The majority of those who have passed through the academy and onto either Alpha or Bri-Stor are now employed full time and making important contributions to their businesses. Others have gone on to further education alongside their employment, supported by the company, such as Gemma Smith – Design Engineer, who recently completed her level four NVQ in advanced engineering at Derby University.

Gemma discussed her apprenticeship experience in a recent interview:

“I first heard about the Alpha Apprenticeship while at the JCB academy. I did my sixth form there and the Apprenticeship Manager told us about Alpha Manufacturing and that there was a job offer/ apprenticeship available. The reason I chose an Apprenticeship over University was because it seemed more practical. I’m more of a practical person anyway so the though of being able to do actual work and get training at the same time was kind of a no brainer.”

Having completed their inductions, the newest intake of apprentices have a full schedule of activities and events to look forward to as part of their studies including the annual soapbox derby, race car build project, Elan Valley team building trip and much more.

From all at Alpha Manufacturing, welcome aboard!

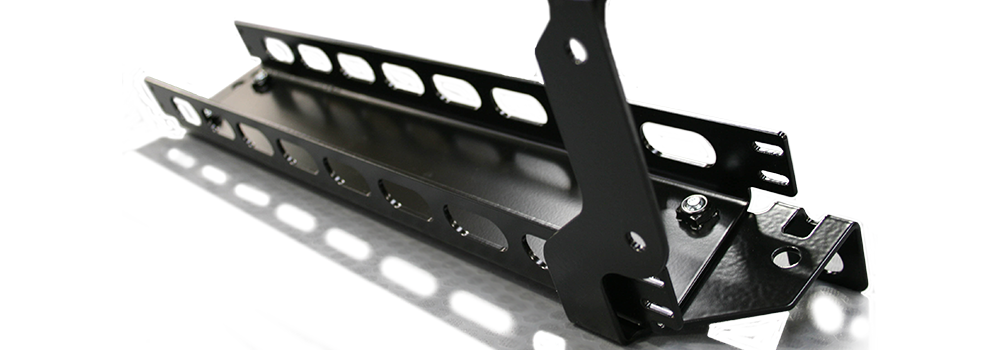

Having originally developed the vehicle partitions for a national roadside recovery fleet in partnership with sister company Bri-Stor Systems, Alpha are now able to offer variants to fit Iveco Daily, MAN TGM, Volvo FL, Mercedes Sprinter, Renault Midlum and D range vehicles.

With roadside recovery businesses currently being adversely affected by social distancing regulations, many are looking for a safe, practical solution which gives their customers peace of mind. Oasis recovery had got in touch after seeing Alpha’s solution in another vehicle and were happy for Alpha to trial the partition in one of their Iveco’s. Having seen the successful installation, they now plan to fit them in the rest of their fleet.

Alpha’s vehicle partitions are provided as a complete, easy to install, self fit kit and can be professionally branded to match any corporate identity for a smart, professional look. For any further information, please get in touch with sales team who will be happy to assist you.

The STOPA extension marks the end of Alpha’s five year strategic investment strategy which was launched back in 2015 and has seen close to £4 million worth of state-of-the-art machinery purchased to elevate Alpha’s factory to the forefront of sheet metal fabrication.

The finishing touch will be to refresh the entire factory shop floor with a paint out to reflect the high the machinery it now houses. A new modern colour scheme has been chosen with white and shades of grey selected to create a modern, clean look. This replaces the traditional, red, green & yellow palette used for years. The new design should better reflect the high-tech status of the factory.

The paint out, which is usually an annual event, is an important process in terms of maintaining health and safety standards, with clearly designated walkways, storage spaces and restricted areas crucial to employee and visitor safety. This also helps in terms of maintaining Alpha’s 5S standards, which in turn, improves efficiency and productivity across the factory.

Once the process is complete later in the week, Alpha will boast a truly industry leading manufacturing facility, both in terms of capabilities and presentation.

Processes and technology used in sheet metal work

A finished product can either be fabricated from standardised parts or manufactured from raw materials, start to finish. The different processes involved will depend on the product requirements and will dictate the company chosen to complete the work. Alpha Manufacturing provides the complete range of sheet metal services, enabling customers to fulfil all their requirements with one supplier.

So from design to delivery, here is a guide to the stages and processes that can be involved in the fabricated metal products industry, and the different technology used for each…

Design

A crucial stage in sheet metal fabrication, the design phase involves the design team working closely with a customer to determine the specific requirements of a project and the best manufacturing approach. At this stage, a thorough process of value analysis/ value engineering takes place to fully optimise the product for manufacture. At Alpha Manufacturing, customers have the opportunity to supply design specifications before working with an in-house team using the latest computer-aided design (CAD) software.

Using CAD software, the design team will:

New Product Introduction (NPI) team members are included in the design process to ensure design specifications and high-quality standards are met throughout.

Prototyping

While not a necessary step in every project, sheet metal rapid prototyping is invaluable as a tool for testing a new design before it is put into production. Alpha Manufacturing uses state-of-the-art machinery to deliver quick turnaround times for prototypes while still ensuring accuracy.

Programming

There are a few aspects to be aware of in the programming process:

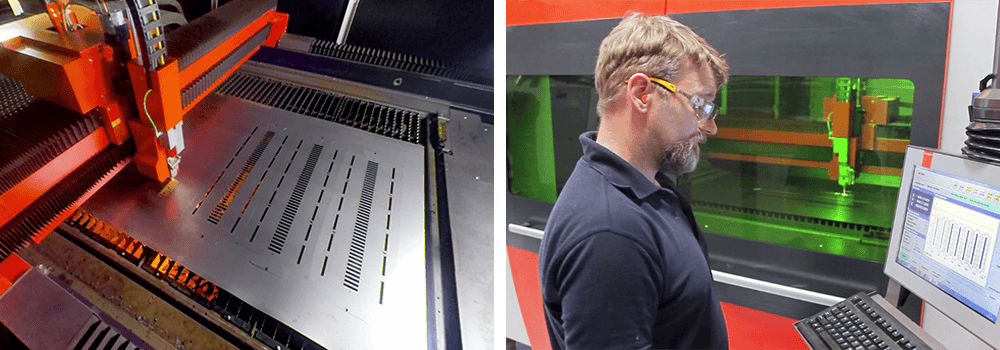

Cutting

While traditional cutting techniques are available, laser metal fabrication technology offers precise and versatile cutting of a range of materials including coated and stainless steel, aluminium, wood and plastics. The innovative CNC (computer numerical controlled) laser cutting machines use the CAD/CAM files optimised in the design and programming stages to guide cutting of the material.

At Alpha Manufacturing, both CO2 and fibre lasers are used:

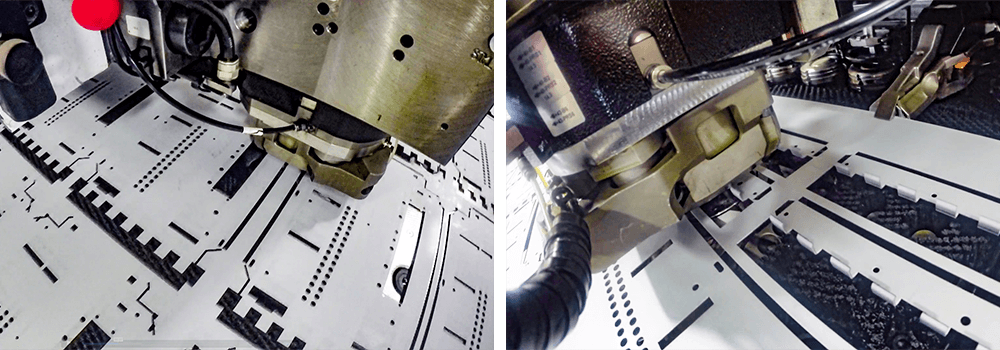

Punching

Punching is the process of creating perforations or forms such as number stamps, ribs, louvres or countersinks in components by applying high force to a tool to ’hit’ the metal sheet in order to indent or sheer through it. Machinery called a Turret Punch uses a hydraulically-powered tool to follow the programmed design, time and time again with no loss of accuracy or quality.

Thanks to consistent significant investment in recent years, Alpha Manufacturing’s CNC punching services are some of the most advanced in the UK. The combination of the fastest machine on the market, the Trumpf TruPunch 5000s12, with the ever-reliable Pullmax 720, allows us to offer a flexible and dynamic CNC punching service depending on the specific needs of individual customers. Alternatively, the TruMatic 6000 Laser / Punch provides the technology to perform cutting and punching in one seamless process, reducing production time and increasing efficiency.

Folding

Folding, also referred to as bending, is pretty much what it sounds like – metal plates are folded in various ways to achieve the desired shape. This can be done using manual press brakes, automated panel folding machinery and/or automated robotic folders to suit any project scope.

Depending on variables such as material, size, quantity and complexity of the parts required, the team at Alpha will use one or a combination of the following machines to perform the job:

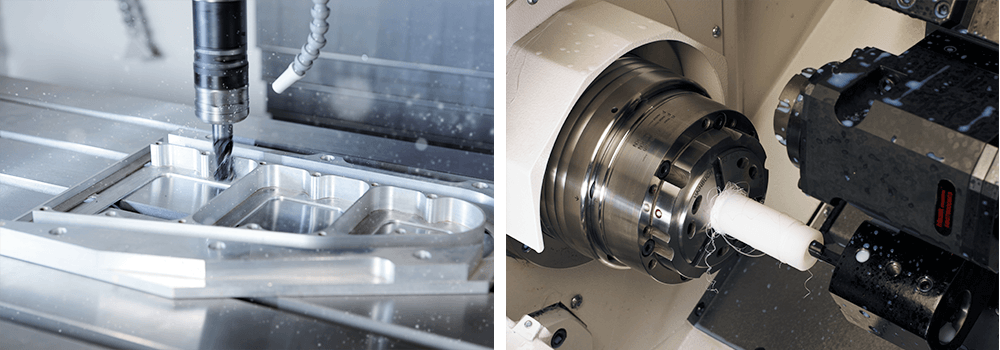

Machining

Machining involves removing material from a solid piece to achieve the desired shape either by turning, drilling or milling. CNC machines like the Mazak Nexus 250 MSY, the Quick Turn Smart 200M or the Mazak VTC-300CII are employed to produce complex precision shapes at high throughput rates.

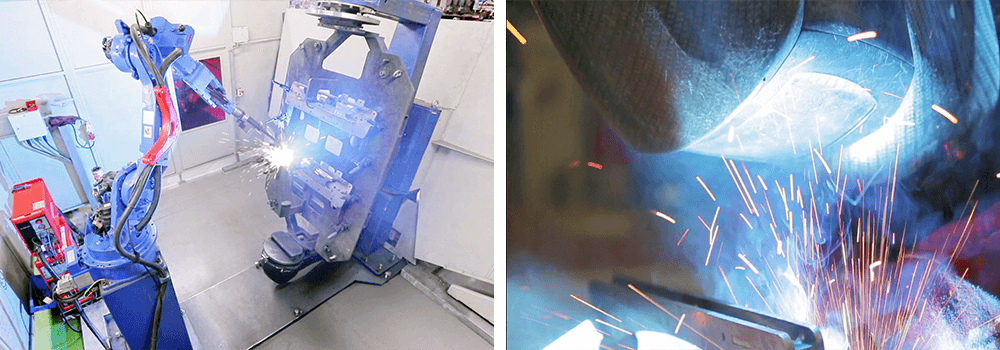

Welding

Welding is the process of applying extreme heat to separate pieces of metal to melt and fuse them together. There are various techniques, some manual and some automated, including MIG welding, TIG welding, spot welding, projection welding and robotic welding. Alpha Manufacturing’s experienced manual welders are qualified to a minimum standard of BS4872, and our robotic welding system boasts high accuracy and repeatability for customers requiring high volumes.

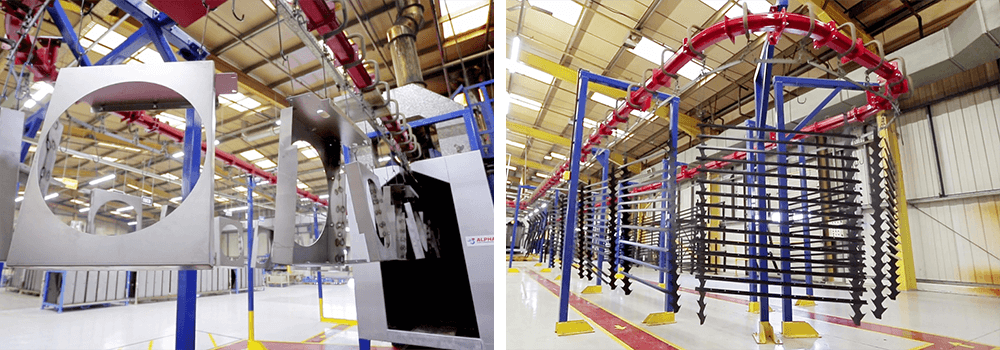

Powder coating

Powder coating involves applying electrostatic powder to a charged metal component before curing at heat to produce a durable coating and finish. Benefits of this process include material protection, colour changes and environmental conditioning. Alpha Manufacturing uses a five-stage OXSILAN® metal pre-treatment technology.

Assembly

Assembly can mean anything from simple weld assemblies to complex electrical integrations (including wiring looms, PAT testing and hardware installation) or those requiring insertions (including pressing studs, nuts or other components to fasten the product together).

Alpha Manufacturing uses a variety of technology and setups to deliver a range of assembly needs such as automated production lines, tower storage systems and engineering drawing displays. CMM technology is then used as part of the quality assurance process to maintain high standards for all finished products.

Latest fabrication technology

Having the most advanced metal fabrication machinery is important to keep up to date with what customers need and what technologies can offer. But this doesn’t stop with the machinery mentioned above. Alpha Manufacturing uses a number of add-on technologies to help improve the speed and quality of product output:

For further information about our metal fabrication processes and what Alpha Manufacturing can bring to your project, please get in touch with one of our expert team members.

This large-scale installation concludes an ambitious five-year investment strategy outlined back in 2015, with the aim of making Alpha the foremost precision sheet metal fabricator in the UK. The focus of this plan was on utilising high-tech machine automation to realise a “smart factory” vision. Now, close to £4 million has been invested to secure Alpha’s position as one of the most technically advanced factories in the industry. The STOPA system has been integral to this, with the first installation taking place back in 2016 alongside a state of the art Trumpf TruLaser 3030 fibre-laser machine. This laser machine and an existing Trumpf TruPunch machine were integrated into the STOPA at the time.

The STOPA system allowed Alpha to begin the process of automating stock storage, movement and transfer between machines, with all raw sheet metal stored in the towers and able to be called on at the touch of a button. This had an immediate positive affect on Alpha’s performance in terms of efficiency and capacity with a dramatic reduction in WIP movement around the shop floor combined with significantly better stock control and management.

Since then, further investment has seen installations of more state-of-the-art automated sheet metal processing machines such as the Trumpf TruBend Cell 7000, TruPunch 7000 and Salavagnini P4 Lean Panel Bender to further bolster Alpha’s levels of automation. The final stage of the five-year plan was to extend the STOPA system further, increasing its storage capacity and removing all WIP from the shop floor. It was also integrated into all areas of production including laser cutting, punching and folding.

The entire system now runs 62 meters down the centre of the Alpha factory and houses in excess of 600 tonnes of raw material and part-processed items with a total of 207 pallet spaces available. The completion of the STOPA marks the culmination of Alpha’s journey to automation which now sets them apart within the industry.

Managing Director Paul Clews explains the strategy and what it now means in terms of Alpha’s service offering:

“We’ve achieved everything we set out to do and more, investing close to £4 million in the right technology and this final investment will take us to where we aimed to be in terms of automation and efficiency. We’re not unique in buying the best machinery, a lot of companies also have high spec technology. Where we aim to differentiate ourselves is in our operations, through the highest levels of efficiency and productivity. What this system gives us is the ability to identify, locate and deliver any piece of sheet steel, punched/laser part or folded sub assembly to any given location by the touch of a button. In doing this we will dramatically reduce the amount of waste from our current processes in terms of both movement of people and transportation of parts.”

With all planned investment as part of the five-year plan now completed, Alpha will continue working to best utilise the machinery and systems in order to achieve total stock/ material handling automation. A new Sage Enterprise MRP was recently implemented, further streamlining the stock replenishment and management process.

These particular screens were fitted into roadside recovery vehicles of one of the leading UK breakdown specialists. Our customer, a leading commercial vehicle management company, had an urgent requirement to supply and fit protective screens in their client’s fleet vehicles. Alpha were able to quickly design an effective solution to fit the Renault, MAN and Mercedes vehicles in their fleet.

The Perspex screens were laser cut to size before being branded in house with vinyl decals. All fixings and bracketry were laser cut, punched, folded and powder coated on site at Alpha to a high quality. Each screen also came complete with detailed installation instructions and illustrations tailored to each vehicle model.

In addition to these screens Alpha have also worked with sister company Bri-Stor Systems to develop partitions which divide driver and passenger in the cab for added protection. These are simple self-fit and available for all makes and models of commercial vehicle.

The enquiry came to Alpha from a retail POS manufacturer who was struggling to meet the unprecedented demand for the units from the leisure and hospitality sector as a result of the current pandemic.

In terms of sheet metal fabrication, the units required laser cutting, CNC folding, welding and powder coating before being assembled complete with dispenser and internal fixings and finally branded with vinyl graphics.

Since the order was placed, Alpha have produced around 450 per day to meet the demand with new production lines created and additional assembly operatives allocated to ensure a constant flow of finished units.

Alpha have maintained a level of manufacturing capability during the recent UK lockdown and following the latest update from the government regarding loosening of the restrictions, are now beginning to ramp-up capacity again.

This means that we are once again on-hand to supply precision sheet metal fabrication services to new and existing customers and particularly those who have seen disruption to their usual supply chains from outside of the UK.

Over the past weeks and months, Alpha have worked tirelessly to plan and implement a host of safeguarding measures, in-line with the evolving government guidelines, to ensure the safety of all employees, suppliers and customers. These include:

Alpha’s number one priority is the safety of all it’s employees, suppliers and customers and these measures have now enabled us to safely begin to increase our capacity and once again offer our usual high level of service.

If your business is struggling to source reliable manufacturing supply through your usual channels and have short to medium term demand, Alpha are available to support until your normal supply can resume.

Please contact our sales team to discuss your requirements and how Alpha can help your business through these challenging times.