Popular Pages

Value analysis/ value engineering (V.A.V.E) is a process of reducing cost / increasing value for the customer in the production of components and assemblies. This is an extremely important exercise for OEM’s when working with a manufacturing partner as products are often produced in high volumes. Any small saving which can be made in the manufacturing stages can equate to huge overall savings across a product lifecycle.

V.A.V.E is often combined with other manufacturing principles such as D.F.M.A (Design for manufacture and assembly) in order to optimize the product in the design phase ahead of production. A manufacturing partner may suggest alternative solutions to achieve the customer requirements. For example, a new tool may be designed to create certain forms when used with a punch or press brake. This may equate to a small upfront cost for the customer but result in a much bigger saving in the long term through reduced processing or increased efficiency.

A manufacturing partner can either be asked by a customer to manufacture a product to an exact specification (Design to print) or to take a more involved, collaborative role in the design phase (Design and specification manufacture).

In the case of design to print projects, there may be an opportunity for the manufacturing partner to review the existing design, using DFMA principles to suggest modifications with the aim of reducing cost. This may include changes to process, for example, CNC punching forms / extrusions as opposed to welding separate parts together, removing processing time, reducing material and ultimately lowering the cost for the customer. Product function and features are also reviewed during this phase, with alternative solutions and possible design changes suggested. These alternative solutions are then tested and costed to assess feasibility. Following this process, the manufacturing partner will propose any design or process changes to the customer, along with a cost analysis.

Where customers require design input from the manufacturing partner, NPI (New Product Introduction) teams will be heavily involved in the V.A.V.E process from the outset. This allows the product to be fully optimised for manufacture with all aspects considered well ahead of production. Materials, features, processes and resourcing can all be considered fully, with a comprehensive cost analysis. Working in this way is the most efficient and cost-effective solution for the customer as design for manufacture insight informs production from the outset. By taking this time early on in a project, the customer is assured that the product is fully optimised for manufacture and as cost effective as possible.

A good example of Value engineering in practice is the electrical enclosure box featured in Alpha’s V.A.V.E video. Working closely with the customer (a global electrical systems manufacturer) from the outset, Alpha were able to make various design suggestions which both improved the products’ functionality and reduced the overall cost to the customer.

By implementing DFMA principles to the design, Alpha reduced the amount of processing required during manufacture and in some cases, completely removed a process all together. Spacers on the rear of the box which allow it to be screwed to a wall securely, leaving space between the box itself and the surface. The had previously been made by welding a washer to the box after manufacture. Alpha instead achieved this by incorporating it into the CNC Punch process. A small tooling investment allowed for the form to be achieved without any welding.

A design change was also suggested to reduce the number of these spacers from four to three without affecting the stability of the box once fixed to a wall. By removing the welding process completely, reducing material by negating the washers and reducing the number of spacers, Alpha achieved considerable savings for the customer whilst also improving the design and functionality of the product. The small savings made on each product, when calculated over the high volumes produced, equate to a significant saving for the customer.

In addition to reducing manufacturing cost, Alpha also made several suggestions to improve the product and reduce manual processing on site by installers. Several conduits knock-out features were added to the sides of the box, using a CNC punch tool. The installer on-site is then able to knock-out the appropriate sections and feed through any cables. This removes the need for on-site drilling of the box, saving time and also improving the aesthetics of the finished product.

Another CNC Punch process was incorporated to stamp electrical earthing symbols onto the inside of the box, instructing the installer where to place certain elements of the internal system. Previously, stickers had been placed here which again, was an additional process and cost for the customer. They could also easily be removed or fall off, whereas the new punch process created an indelible stamp.

Alpha’s experienced NPI and engineering teams have a wealth of knowledge in precision sheet metal fabrication and work with each customer to value engineer their products where required. Often, there are manufacturing considerations that the customer is not been aware of or alternative processes that can be utilised. If you have a product you’d like to discuss, get in touch with our sales engineers who are always happy to discuss product design and offer V.A.V.E advice.

The Coast to Coast Challenge will take place over the weekend of 18th Sept (Fri) – 20th Sept (Sun). The ride will follow the Hadrians cycleway and is approximately 125 miles from Siloth to Tynemouth. The route dictates that riders will need to on either a mountain or hybrid bike. Accommodation is yet to be confirmed but participants will be required to pay a £20 deposit to confirm their place. A maximum of 10 places are available and will be allocated on a first come first serve basis. A suggested minimum of £100 per rider to be raised for Katharine House.

Date: 18th-20th Sept

Route: Hadrians Cycleway (Siloth-Tynemouth)

Bike: Mountain/ Hybrid

Accommodation: TBC

Deposit: £20

Minimum Raised Target: £100

The event, scheduled for September, will see the group travel up from Stafford to Siloth on the East Coast near Carlisle, where they will set off on a 125 mile journey along Hadrian’s wall all the way to Tynemouth on the West Coast.

The ride is planned over two days, with a stop off over night along the route. A support group of Bri-Stor Group employees will also follow in a Bri-Stor Systems Welfare vehicle and will be on hand to supply refreshments and support throughout.

The event is open to all levels of experience and experienced cyclists and novices alike have already signed up to take part.

As with all Bri-Stor Group fundraising events this year, all proceeds will be donated to the nearby Katharine House Hospice, who offer crucial care and support for people with advanced life-limited conditions across mid-Staffordshire.

If you’d support the Coast to Coast event, visit the just giving page and click donate.

Gemma has been studying manufacturing production engineering at Derby University for the past 4 years whilst also working at Alpha as part of thee design team.

With her studies due to come to an end this year, Gemma has decided to take on a unique fundraising activity – The UNI Challenge. With no prior experience, she has committed to riding a Unicycle the entire combined length of both Alpha and Bri-Stor’s factory’s (around 600 meters.)

“I’m always up for a challenge and especially something funny or unique. It’s going to be a real challenge though as I’ve never ridden a Unicycle in my life. I think it will definitely make the end of my degree memorable and hopefully we’ll raise plenty of donations for Katharine House!”

The Katharine House Hospice was chosen as the Bri-Stor Group’s charity partner for 2020 following an employee nomination process. Based in nearby Stafford, they off crucial and valuable holistic care and support for people with advanced life-limited conditions.

Over the next 12 months, employees from across the Bri-Stor Group will be participating in a host of fundraising events, with all proceeds passed on to Katherine House.

In total, around 60 visitors came to have a look around Alpha and Bri-Stor’s facilities and see what the Bri-Stor Group apprenticeship programme has to offer. They were also given a presentation by group apprentice manager Will Davies-Hill before taking a guided tour of both factories. Current and former apprentices were on hand throughout the evening to answer any questions and offer insight into their experiences with the company.

On display during the evening were several examples of Bri-Stor Systems products and Van conversions, Alpha manufactured products and creations of apprentice projects, including the ever-popular Caterham race car. Following the open evening, applications for the apprenticeship preprogramme have been trickling in in and we look forward to welcoming potential candidates for interviews in the near future.

Apply Today

Both teams have made strong starts to the season, as coach Andrew Gay explains:

Blurton Arrows Red U14s

“Another really strong start to the season sitting second in the league with two games in hand on first place, were top of the group in the group stage of the Staffordshire Area cup, and have just been chosen to represent our centre in the Doug brown Memorial tournament.”

Blurton Arrows Yellow U14s

“This season was just about getting the lads used to each other with being together for the first time this season but they are far exceeding what we expected from them. They’re sitting

fourth in the yellow league with four games in hand on the third-place team and games in hand on second and first. Third place is well within their sights which would be a great achievement in their first season together.”

This sponsorship follows Alpha’s partnership with another local team – Leek Town Wildcats under 8’s girls’ team who had great success in their first full season last year. They managed a local cup double, winning both the Staffordshire Shield trophy and Staffordshire cup winners cup.

Alpha are delighted to be in a position to support the development of local talent and wish both the Blurton Arrows and Leek Wildcats the bets of luck for the season.

The ever-popular event offers young people interested in an engineering career the opportunity to discover what vocational options are available to them. In attendance will be current and former apprentices from both Alpha Manufacturing and Bri-Stor Systems, team managers and even company Directors to answer any questions on the night.

The evening will begin with a welcome by group apprentice manager William Davies-Hill before a full tour of Bri-Stor and Alpha facilities. This gives the young visitors and their parents the chance to see first hand the processes that take place, the machinery employed and the facilities as a whole. Following the tour, visitors are invited to attend a Q&A session where they can discuss in more depth the options available to them after school.

Many of Bri-Stor Group’s current and former apprentices visited the open evening before deciding to take an apprenticeship at either Alpha or Bri-Stor. They discuss this and much more about their experiences in the video below. Gemma Smith was one such apprentice, she discusses her reasons for choosing an apprenticeship over other options.

“The reason I chose to do an apprenticeship over University was more of the fact that it’s more practice. I’m more of a practical person anyway so the thought of being able to do actual work and get training at the same time was kind of like a no-brainer and I think it’s a no brainer for anyone who wants to work in engineering, or business or anything really.”

If you’re interested in a career in engineering, or even if you’re not sure what you’d like to do following school, simply register here and come along to our open evening at 5.30 on Thursday 13th Feb and see what a Bri-Stor Group apprenticeship has to offer!

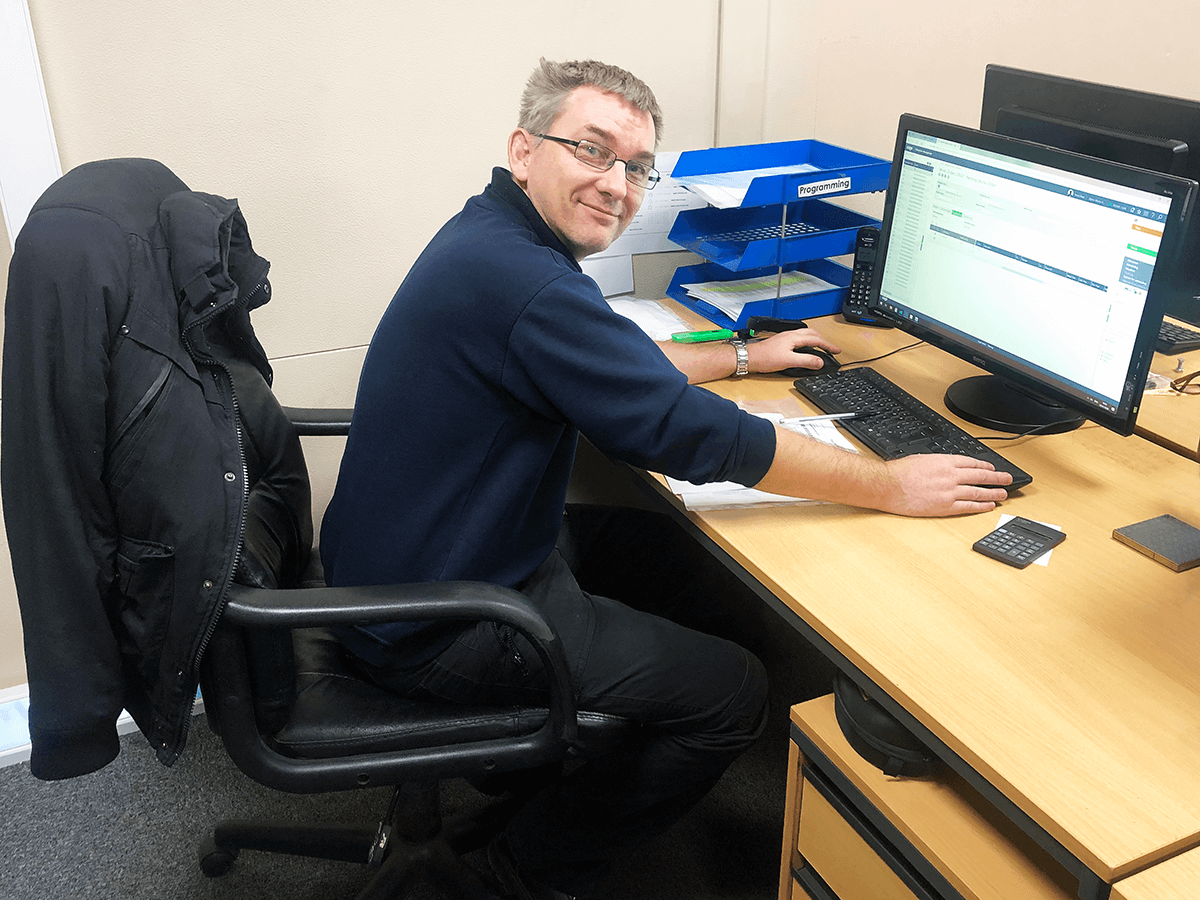

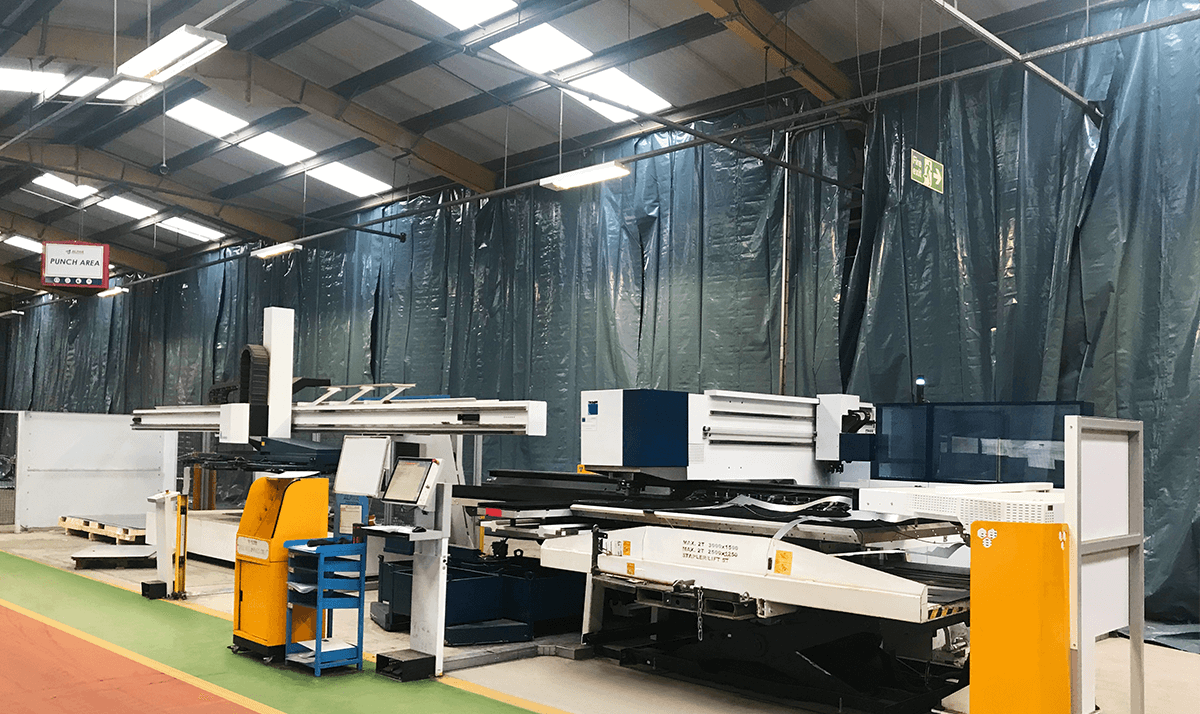

Steve has seen many changes during his fifteen years, most notably the move to the current site from the original factory at Hixon airfield where he worked in the beginning. After working as a punch operator, Steve moved over to assembly for a brief time before taking his current position as programmer, where he has worked for the past three years.

“So much has changed here since I started, from the factory, to all the new machinery and the management. We’ve come a long way and you can see even now, there’s still big changes happening. The best part of my job is the people I work with day to day, a lot of us have been here a long time and we all get on well in our office”

Outside of work, Steve is a keen driver and race car enthusiast, his own Mevster kit car over a six-month period. He is a member of many kit car enthusiast clubs and regularly attends meets with fellow owners. Steve even uses his hobby to raise money for local causes such as Claires House Hospice through events and sponsored drives.

Steve, along with others from across the Bri-Stor Group who have also achieved long service milestones will be recognised around the business over the coming weeks as well receiving an extra day’s annual leave.

Over the next two weeks, 80 cubic meters (160 tonnes) of concrete will be poured ready for the machine construction to begin in January, with an expected completion date of 30th March

The extension will see a further 10 bays added to the existing 6, increasing storage capacity from 67 pallet spaces to 207. Once complete, the entire system will run 62 meters down the centre of the factory and will be able to house in excess of 600 tonnes of raw material and WIP. Dedicated automated picking carts, strategically located in line with the overall logistics vision for the factory, will allow operators to call on any stored materials and have it delivered to them at the touch of a button. The system will also be integrated into all punch and laser/ punch combination machines, allowing raw sheet metal and part processed items to be delivered via input/ output carts. Once that process is complete, parts will be automatically put back into storage ready for the next process, without any manual handling.

This latest outlay concludes Alpha’s strategic 5-year investment plan, set out in 2015 and is the final step on the journey towards factory automation. The original STOPA system was installed back in 2016 and dramatically improved efficiency through better stock handling and easier inventory management, whilst reducing manual handling and movement of WIP around the shop floor. Since then, 4 automated Kardex shuttle vertical storage systems have also been installed around the factory to further reduce the amount of WIP on the shop floor. The new extension to the STOPA will completely eradicate this with all raw material and parts stored in an automated system. Unlike the original STOPA, which could only store flat sheet metal, the new installation is also capable of storing folded parts.

Managing Director Paul Clews, who has overseen the investment plan since 2015, is delighted with the progress made:

“We’ve achieved everything we set out to do and more, investing close to £4 million in the right technology and this final investment will take us to where we aimed to be in terms of automation and efficiency. We’re not unique in buying the best machinery, a lot of companies also have high spec technology. Where we aim differentiate ourselves is in our operations, through the highest levels of efficiency and productivity. What this system gives us is the ability to Identify, locate and deliver any piece of sheet steel, punched/laser part or folded sub assembly to any given location by the touch of a button. In doing this we will dramatically reduce the amount of waste from our current processes in terms of both movement of people and transportation of parts.”

Once completed in early 2020, Alphas key objective is to achieve total stock/material handling automation. Coupled with the recent introduction of our new group MRP system Sage Enterprise, Alpha aims is to also automate the replenishment of various types of stock, removing the requirement for the manual ordering process on certain lines of stock.

Rob joined Alpha back in 2003 from cold rolled section manufacturers Hadley Industries where he had been for 14 years and at the time, was the only member of Alpha’s sales team. Along with years of engineering experience and understanding, Rob also brought a more structured approach to sales, quickly implementing a range of new processes and systems. A customer-centric approach also allowed Rob to build strong relationships with key clients, something which he still prides himself on today.

In more recent times, Rob has further modernised Alpha’s sales department by transitioning from a traditional outbound strategy centred around telesales and networking events, to utilising digital channels to drive inbound enquiries. In addition, Rob has expanded his team to include sales engineers, dedicated estimators and key account managers, whilst also adding in-house marketing resource. A new CRM system was implemented alongside lead generation KPI’s, bringing further structure to the sales team. As a result, Alpha has been able to remain on target with its ambitious five-year plan, outlined in 2015 with the goal of doubling turnover by 2020. Record breaking turnover in recent years is a reflection of Rob’s dedication and drive over the past 16 years and the promotion to Director is reward for his efforts.

Of all his achievements to date, Rob highlights the role he played in developing Alpha to the point of outgrowing its original site at Hixon Airfield and its relocation to the current Pasturefilelds lane site back in 2006 as his proudest. Rob explained:

“Back in 2003, Alpha was still in it’s infancy and although we’d started to subcontract sheet metal services, it was still quite ad hoc. It was clear that there was massive potential to grow commercially and I was excited to be a part of it. Since then we’ve gone from strength to strength and there have been so many proud moments to date. The move to the new site was such an important moment, which has allowed us to make huge strides since. We are still as ambitious as ever to build on our recent success and to continue improving”

Back in January 2019 Paul Clews was appointed Alpha Managing Director and this latest promotion coming so soon after, again reaffirms the positive direction that Alpha are heading in over the coming years. Paul was delighted to announce the appointment.

“This promotion is the deserved recognition for Rob’s continued hard work and dedication to the business. Not only is Rob an exceptional sales person but also a great engineer. This enables him to work with clients from the start of projects, promoting value engineering and best practices from the outset, a rare and valuable skillset which makes him a true asset to the business. This structural change further bolsters Alpha’s commitment to growth and expansion, which is key to delivering our next 5-year plan, set to follow on from our 2020 vision. Rob’s continued development and evolution of our sales strategy will be key to us achieving our goals.”

In his new role, Rob will continue to manage the sales team on a day to day basis whilst remaining a key member of senior management. A new 5-year plan is set to be outlined ahead of 2020 and as part of this Rob will aim to continue Alpha’s commercial growth, building on existing customer relationships as well as expanding into new markets.

Donations were taken throughout the day around both Alpha and Bri-Stor Systems as the whole Bri-Stor Group embraced the seasonal cheer with their cheesiest Christmas jumpers. All funds will be donated to nearby Katharine house.

The Hospice, based in Staffordshire, do valuable work in the local community, providing free hospice care services for those with terminal illnesses. The Bri-Stor Group are proud to be supporting Katherine House during 2020, following a recent employee nomination process. Throughout the next twelve months a series of fund-raising events will take place across the Bri-Stor Group, with all proceeds donated in support of Katharine house.

The 2019 Christmas jumper day was the first of these events and was a great success.

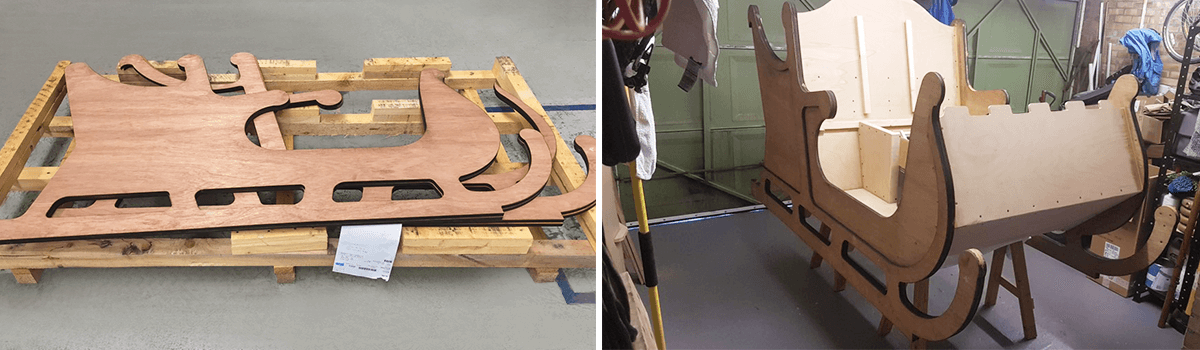

Members of the club had approached Alpha to laser cut the frame profiles of the sleigh and also supply a leisure battery to power its lights. The president of the club, along with senior members visited the factory last week to show off the finished sleigh and to thank Managing Director Paul Clews and Commercial Manager Rob Eley for their support.

Over the next three weeks, Santa will be out and about in his new sleigh, visiting as many of the local towns and villages as possible, a local tradition stretching back decades. Local children fill the streets of along the route to catch a glimpse of father Christmas as he passes by.

Members of the Rotary club will be on hand taking donations from local residents as Santa passes by. The Rotary club is a charitable organisation consisting of local business people and professionals, both active and retired who aim to serve the local community through fund raising and social activities.

All at Alpha wish Santa the best of luck on his travels over the next few weeks and hope he raises plenty of donations for local causes.

The 1st year apprentices will be accompanying apprenticeship manager Will Davies Hill as he visits various local schools to introduce them to the Bri-Stor Group. Presenting to year 11 students, they will discuss their experiences during their first year, covering training, projects, events and their studies so far.

This gives students who may currently be considering their post-high school options a unique insight into life at Alpha from an apprentice’s perspective. It also clearly shows the path for career progression with examples of past apprentices who now have important full-time roles within the business.

Over the next few months, Will and his young colleagues will visit as many of the local schools as possible, encouraging students to visit the annual apprentice open evening in February and to apply once applications open in the new year.

Chloe Sales joined Alpha Manufacturing during 2019 after sending in an application back in August, which immediately caught the eye of production management.

“Being a female doesn’t stop me doing a ‘man’s job’” Chloe wrote in her impressive application. Days later, she had met with management and had accepted an offer of employment as a welder. Prior to applying for the job with Alpha, Chloe had trained as a welding apprentice at Stoke-on-Trent College, where again, she’d been the first female to do so.

Having passed the course with flying colours – three distinctions, two merits and a pass, Chloe was named STEM Apprentice of the Year 2019 by Stoke-on-Trent College. Her achievement was noticed by local press who were impressed by her “can do” attitude and positive outlook. Since the award, Chloe has featured in various articles in local press, with more still to be published.

Having been with Alpha for the past three months, Chloe is enjoying her role and is as determined as ever to be a success, proving those who doubted the career choice wrong. She told local Newspaper, The Sentinel:

“No-one thinks of welding as being a woman’s job. It is seen as noisy, harsh and dangerous, and I think people were worried that I’d find it too exhausting – both physically and mentally, being a woman in a male-dominated environment.”

“I love my job because it’s different. I like doing my own thing and being in my own lane. I enjoy the variety of work and the feeling of satisfaction that I get when I’ve finished a job. It’s well paid too. I don’t have a problem with being a woman in a man’s environment. I feel like I’ve found the right career and I’m looking forward to seeing what the future holds.”

Not content with just making a success of her own career in a traditionally male-dominated industry, Chloe is also proactively encouraging other females to consider taking a similar step. In her free time, she visits schools to give talks to girls about STEM careers.

“Everybody told me not to do it. That’s why I go out to schools and tell other girls not to listen to their friends or people who want to put them off. They can do it. I did. And I love it.

“I never had anyone to look up to in a careers way, so I’d love to be able to help at least one person, to inspire someone not to give up and to follow their passion.”

The recognition that Chloe has received recently is no more than she deserves and she hopes to continue to work hard at Alpha whilst spreading the positive message to other females in a similar position through her school visits.

As sponsors of the team, we like to follow the girls’ progress closely. Last year, Alpha supplied kits and training jackets for the team and have continued to support this year with a new set for the season.

The Wildcats enjoyed a great day out as Mascots for the Ladies 1st team, who battled to victory in a 7 goal thriller in their Women’s FA Cup Preliminary Round game against Kidderminster Harriers. Coming out eventual 4-3 winners, the 1st team ladies put the icing on the cake for the young Wildcats.

The young team enjoyed success themselves last year, completing a cup double in their debut season after winning both the Staffordshire Shield trophy and Staffordshire cup. We’ll be keeping up to speed on the progress of the Wildcats over the course of the new season and wish them the best of luck again!