Popular Pages

I started my career in sheet metal when I was 19, starting out as a welder with a leading Turf machinery manufacturer in 2008. This is where I learnt the basics of metal fabrication, welding various turf machinery products every day and developing my skills. It was here I discovered a passion for manufacturing and particularly the processes involved.

From there, I moved around different areas of production, spending time as a Laser Operator and Press-Brake Operator. Eventually I moved into design as a CAD (Computer Aided Design) Engineer and here I saw the other side of Manufacturing – the work that went into the concept of a product and its pre-production. I learnt all about design for manufacture principles and value engineering which gave me a better understanding of the end-to-end manufacturing process.

Around this time, I started studying for a Higher National Diploma in Mechanical Engineering and moved into production scheduling, responsible for co-ordinating the production of new orders and planning capacity. The knowledge and understanding I gained here was priceless and I soon became a Production Manager for a Laser Cutting company. I loved the role and the responsibility of orchestrating people, material and capacity to achieve strict deadlines. The fast-paced nature of production is what really excites me.

The move to Alpha Manufacturing as Production Manager was a big one for me in 2019 and now, two years on, I can honestly say I love my job. Being a target driven person, I thrive on seeing my team hit our KPI’s and achieve deadlines. I love the dynamic nature of the work too – our portfolio of parts and assemblies is ever changing as new customers come on board and this keeps things fresh. Every day is different and presents its own unique challenges.

My next career goal is to become Senior Production Manager responsible for all production departments. I’m really ambitious and the good thing with manufacturing is that there’s always more to learn. The production challenges of today are the engineering knowledge of tomorrow. Ultimately, I’d like to become an Operations Manager and hopefully with experience and continued hard work I’ll get there.

If I were to give any piece of advice to somebody just setting out in a manufacturing career, it would be to let curiosity be your compass and gain inter-departmental experience to understand the varied perspectives of production. I would also stress the importance of being hands on and accepting that success isn’t the perfect narrative; plenty of failures will occur.

|

ABOUT THE AUTHOR

Sean McColl has 13 years’ experience in engineering with a wealth of knowledge in all departments of sheet metal fabrication. Sean is responsible for overseeing Alpha Manufacturing’s production team, ensuring deadlines are met and quality remains high across the board. He’s ambitious about his career and aims to eventually become an Operations Manager. Outside of work, Sean has recently become a proud dad and loves spending quality time with the family. |

Staying connected was one of the biggest and most unexpected challenges of 2020. Not only for business but for families, communities and wider society. At Alpha Manufacturing, as with most other companies, we had to adapt quickly to people working from home, limiting numbers attending meetings and restricting visitors.

Before the pandemic hit in March, meetings in person were unrestricted in terms of attendees and face to face meetings were viewed as essential building blocks in forming new business relationships. All employees were required on site during office hours, regardless of the nature of their role.

Now, after three lockdowns we’re all now accustomed to virtual meetings, video calls, remote working and digital collaboration. It has become as efficient and productive to perform a business meeting over Zoom or Teams as it is in person. Instant chat is more effective than email in many cases, and we’ve all been surprised at how much we can get done from the comfort of our homes.

There are so many benefits to adopting digital and if there’s one good thing that will come out of the pandemic for business, it’s that a light has been shone on communication technology. I have to wonder, has this changed the future of business communications both internally and externally permanently? I’m inclined to think so.

Personally, my job doesn’t require full attendance at work and most can be done from home. However, being new to my role, the need to learn was the factor that kept me in the office. I also actually enjoy the routine of getting ready in a morning, commuting, having social interaction at work and learning on a day-to-day basis from those around me.

However, having seen the way Alpha Manufacturing has successfully adopted new digital technologies, I think it’s clear that the benefits of digital definitely outweigh any drawbacks. Internal communications, maintaining customer relationships and reaching out to potential customers have all been enhanced by a more digital approach.

Our “Stronger Together” ethos could easily have been tested by COVID but through digital platforming and communication, it has reinforced the strength of our team and underpins greater collaboration with customers, suppliers and partners.

Digital transformation is here to stay.

ABOUT THE AUTHOR 20-year-old Corey Hammond is an Alpha Manufacturing Graduate Apprentice who has recently started a Business Management Degree with the Open University. He’s also the youngest member of Alpha’s sales team, training to become a key account manager. Outside of work, Corey is a fitness fanatic who enjoys kickboxing and Jujitsu.

One thing that sets Alpha Manufacturing apart in our market place is our ability to offer the entire sheet metal fabrication service in house. This means we can supply a complete end-to end, turnkey solution for our customers. The first stage of this solution is always design and that’s my department. I work on both new part design, and improvements of existing parts.

When a new product comes to Alpha Manufacturing, it’s assessed by our NPI (New Product Introduction) team. They will determine whether it’s feasible for it to be manufactured by us, exactly what is required in terms of Design and which processes will be needed to produce it.

At this stage, an APQP (Advanced Product Quality Planning) meeting takes place between Design, NPI, Quality, Production and Sales. The aim is to define exactly what is required of each department in order to produce the particular part.

The Design team is responsible for any redesign work, creating drawings, prototyping and creating any JIGS or fixtures needed for any of the manufacturing processes. Once any new part or product is manufactured it is first checked by the Quality team, who will perform an ISIR (Initial Sample Inspection Report) to ensure all dimensions and specifications are correct and that overall, the part is correct for further manufacture.

Our Design team also constantly looks for opportunities to implement Design for Manufacture principles in all new and existing parts, which makes production more efficient and cost effective. Sometimes, there’s a sudden requirement which needs urgent input from the Design team.

One particular example was a welded assembly which required a fixture to be designed and manufactured but the customer required the part on a quick turnaround. The solution was to incorporate slots and tags into the design, allowing the parts to self-locate, negating the need for a fixture and speeding up production.

After approval from the customer, I re-designed the part and programmed the parts for the Laser Operative. Once Laser-Cut, the parts were folded and then welded to the new drawing before being polished.

Once complete, I managed the part through packing and despatch ready for delivery to the customer. This is a simple example of how Alpha Manufacturing are able to offer the entire sheet metal fabrication service from design to delivery. Even in short timescales, we can be flexible enough to respond with innovative design solutions.

ABOUT THE AUTHOR

Gemma Smith recently completed her Manufacturing & Production Engineering Degree at Derby University after 5 years as a Higher Apprentice with Alpha Manufacturing. She is now a key member of the Design Team, working as a Production Engineer responsible primarily for design work for Alpha Manufacturing’s stainless-steel department.

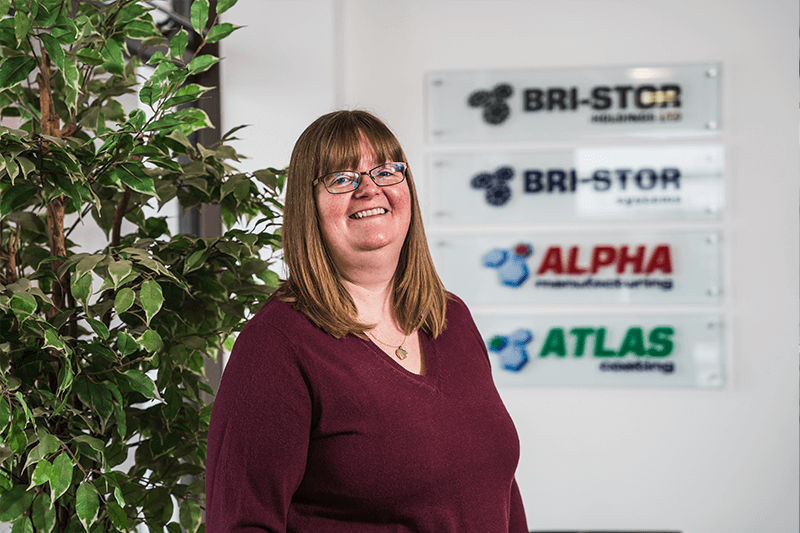

At just 17, Karen joined the Bri-Stor Group as a receptionist. Unsure of her career path at that point, she loved the vibrant atmosphere of the Bri-Stor Group. Today, almost three decades on, Karen holds the most senior HR position across the Group, looking after the employment rights and welfare of almost 500 people as well as leading on recruitment and the Group’s career development programme.

Working closely with the senior management teams across all three of the Bri-Stor Group businesses and also supporting Apprenticeship Manager, Will Davies-Hill, Karen never takes for granted the opportunity she has to positively influence the career path of people joining the Group.

Karen tells us more about her role and her passion for people development: “When I joined the business, I guess I wasn’t really sure where I was heading. I loved the ‘front of house’ part of my job and engaging with colleagues and visitors and in many ways my role in the business naturally evolved. Back in the 90s the company was very different to the Bri-Stor Group of today and people often ‘flexed’ in their positions to fulfil a range of duties. My HR role started just like that. Initially I got involved in admin work, supporting with some payroll duties but I quickly realised that I loved the HR element of my role and that’s how my career kicked-off.”

Recognising Karen’s natural flare for HR, the business sponsored her to complete the CIPD Human Resource Management qualifications which, along with an ongoing programme of professional development, has resulted in Karen becoming a highly accomplished and skilled HR practitioner. Yet, setting aside the essential work she completes to keep the Group’s HR function operating at extremely high standards, Karen remains personally and professionally committed to the development of every colleague in the business, including the Apprentices.

Karen continues: “When I joined the business, I was given every opportunity to advance my skills, and therefore my career and I feel passionate that every member of the Bri-Stor Group family can access the same opportunity. I work very closely with Will Davies-Hill to ensure that our Apprenticeship Scheme meets the needs of young people coming into the workplace and I take this responsibility very seriously. In truth, you’re in work for a very long time and as I know from personal experience, the opportunities you seek out in your early career-years really shape your future.”

In 2021, the Bri-Stor Group will recruit 15 Apprentices across Bri-Stor Systems and Alpha Manufacturing and Karen has these words of advice: “The Group is a dynamic, pacey environment where you’ll learn fast and get maximum support and opportunity. That said, you’ll be expected to bring your ‘A Game’ every single day – but the rewards are there for those Apprentices seeking an exciting future in engineering. We’re looking forwarding to meeting you.”

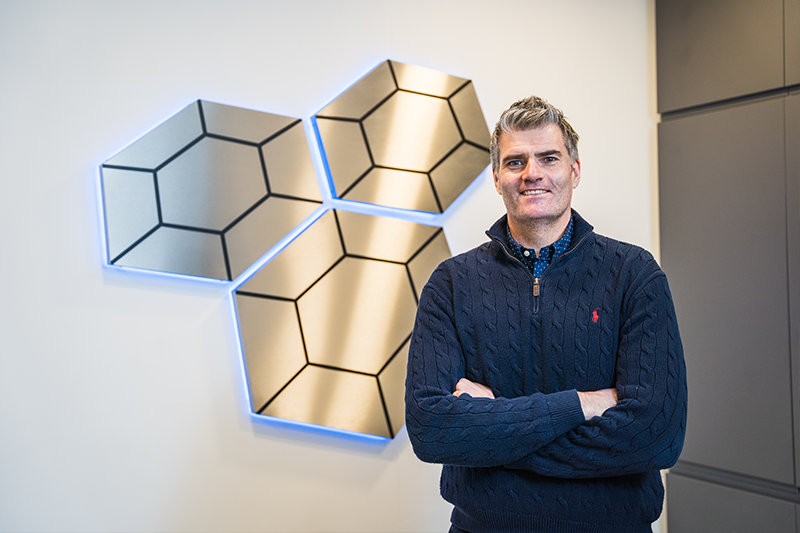

When Paul Clews started his career at 16 as an Apprentice Engineer little did he know that by 43 he’d be the Managing Director of two of the region’s most dynamic engineering businesses – Alpha Manufacturing and Atlas Coatings. With a career very much grounded ‘on the tools’, Paul’s hard graft and determination has earned him immense respect from colleagues across the Bri-Stor Group.

This is Paul’s story. A bright lad with big ambitions, Paul had a passion for mechanics and design engineering. Completing his GCSEs, he had every option open to him to advance his education but struggled to see how A Levels and a degree would suit him. Paul shares his thoughts on his early career choices and how it has influenced his career today: “Right the way up to the completion of my GCSEs I thought I’d take the A Level and Uni route – I was pretty committed to an engineering degree, but something didn’t feel right. It was through talking to a neighbour that I heard about an Apprenticeship Scheme at Belle Engineering and the penny dropped – the opportunity to earn money and gain engineering skills sounded like the perfect combination.”

Gaining an Apprenticeship at Belle Engineering with just two places available and 30 applicants was gruelling and Paul, tenacious even back then, gave it his all to secure a valuable place, Paul continues: “I worked hard to get onto the Apprenticeship, and this really spurred me on, I thought if I can be successful doing this, what else can I achieve? The next four years were hard graft splitting my time between work and studying for my BTEC National Diploma in Engineering, but everything started to click. Learning while working gives you such a solid grounding and I embraced every opportunity to learn all the shopfloor skills.

“In year three and four of my Apprenticeship I moved into office functions which really whet my appetite for all things design, it was in these two years that I really decided that I wanted to focus on becoming a Design Engineer. By year four, I’d achieved my HND in Engineering and if I’m being brutally honest the only poor choice I’ve made in my education and career was not grasping the opportunity to complete my full engineering degree. I think by that time I was really ready just to focus on work.”

For the next 10 years Paul progressed rapidly through his career from Tooling Design Engineer to Production Manager in just a few years. It’s in his role as Production Manager that Paul cites the implementation of Lean Manufacturing principles as a career highlight – an accomplishment that is considered world-class amongst the manufacturing community. In 2010, Paul makes his move to Alpha Manufacturing as Production Manager and it’s here his career advances even further. Paul continues: “I’ve got so much respect for Belle Engineering; at the time I was there I was given every opportunity to further my career and that’s what drew me to the Bri-Stor Group and the role at Alpha Manufacturing. The opportunity to grow and achieve your full potential is a value that really stands out in this business.”

Today, Paul retains the same strength of character that spurred him on in his early career days as a 16-year-old Apprentice, and while he carries the huge responsibility of leading a team of over 200 people, he remains committed to the professional development of the people around him, he concludes: “Everybody deserves a chance to succeed and achieve their ambitions if they’re prepared to put the hard work in. I look back on my own career and I’m thankful to all the people that took the time out of their own day to show me the way. Now, almost 30 years on, I take every opportunity to nurture the Apprentices in this business, this really is my opportunity to give back.”

Growing up in Staffordshire, just a few miles from the family business, Martin Smith spent much of his childhood watching his parents build Bri-Stor Systems Limited (Bri-Stor is an abbreviation of British Storage). Today, as CEO of the Bri-Stor Group, he reflects on his own career and the tough lessons he learned along the way.

“Growing up in the 80s and 90s I didn’t see a lot of my parents; they were always at work and I suppose looking back I didn’t really have a full appreciation of their hard work and what it meant for my future. At that time, I spent a lot of time playing sport, in particular cricket and hockey and enjoyed playing at a reasonably high level. As for school, I was a challenging lad to say the least, I was a bright kid and I loved my school, but I was quite mischievous and was often looking for clever ways to distract my mates and the teaching staff. That said, I did pretty well in my GCSEs and A Levels, and the turning point really came for me when I was 18 and took up a place on a four-year degree at Bath University, studying International Business and Foreign Languages.”

In year three of his degree Martin started a role at Peugeot, based in Paris, a turning point in his future, as he explains: “my role at Peugeot really changed my view of the workplace. I’d always done well academically but this was my first opportunity to really get stuck into something outside of education. It was an incredible experience and built my confidence no-end. It was never a given that I would work for Bri-Stor Group, far from it, my dad’s view was “you make your own way son” so that’s exactly what I did. I worked flat out at Peugeot, rarely seeing anything other than the inside of the office or my tiny flat – but it was a solid grounding.”

Graduating from Bath University and gaining experience in the world of manufacturing and engineering, Martin felt he was set for a career in the family business, he tells us what happened next: “I can recall the conversation with my dad about joining the business and he was adamant that I had to go and find out what my value was in the world of work. What he meant was, go and get three job offers and we’ll talk about a job at Bri-Stor Group. So that’s what I did, I got offers from three global management consultancy businesses and my dad’s response? “Well done son. You can have half the salary and you can start in the paint shop, on the night shift” – so that’s exactly what I did.”

For several years Martin worked night shifts, day shifts and a combination of the two. He worked in all departments learning the shopfloor skills required to run the business and eventually became Production Manager in Alpha Manufacturing, he continues: “It was pure hard work, but to this day I remind people that you shouldn’t expect somebody to do something you wouldn’t be prepared to do yourself. That mindset has stayed with me throughout my career in the Group and is a strong part of our culture today. I look at how hard the teams work throughout the business, but what really stands out is the strong team ethic that underpins it all. As we welcome new Apprentices into the business, I know we are giving them the very best opportunity to develop a successful career. In truth, if you’re wondering if an Apprenticeship will broaden your horizons, then read about Paul Clews’ career – he is the very essence of how an Apprenticeship can pave the way for a bright, successful future.”

What are you looking for in this year’s Apprentices?

“As with every cohort of Apprentices, we expect to see determination and the willingness to try new skills. For many of this year’s intake, regardless of age, they will have experienced a really disruptive education, so we are looking for Apprentices with a really strong, positive mindset. Joining the Bri-Stor Group is the start of an exciting chapter.”

Nearing the completion of his NVQ in Mechanical Engineering at college, Stephan was weighing up options when he met Bri-Stor Group Apprenticeship Manager Will Davies-Hill, as he tells us: “I wasn’t really sure what I wanted to do after completion of my NVQ but when Will visited my college and told us about the opportunities at Bri-Stor Group as an Apprentice I was really intrigued.”

Stephan took part in the Bri-Stor Group Open Day and was struck by the scale and professionalism of the business. Immediately drawn to the manufacturing capabilities of Alpha, Stephan applied to join as an Apprentice in 2019. Stephan tells us more: “We got the opportunity to see all the manufacturing equipment in action and I was really impressed by the Stopa and in particular the Bend Cell – seeing the huge levels of automation really changed my perception of sheet metal fabrication. I think in my mind I was picturing a dirty workshop with a few bits of kit but Alpha couldn’t be further away from that perception – it’s a world-class business and as a consequence we’re involved in the manufacture and production of some pretty impressive fabricated products.”

Stephan really enjoyed year one and although there is a lot of classroom time at The JCB Academy, the relaxed, informal approach to teaching was perfect for Stephan’s learning style, as he expands: “we learnt a lot in year one but it didn’t feel like learning. The tutors really respect the fact that we’re working guys, not kids, and that makes such a difference.”

In year two the Apprentices are part of the Rotation Programme and get the opportunity to experience every operational function in the business. “I’m enjoying some departments and process areas more than others, but that’s what this is all about – seeing what you like, and how that matches up to your skills,” explains Stephan. “By being part of every function in the business, regardless of how much you like it, you can see the total process which is important. Understanding the impact of one process on another dramatically improves efficiency and removes mistakes.”

Would you recommend the Alpha Manufacturing Apprenticeship Scheme? “It’s a tough world right now and I feel secure in my role at Alpha. I know the business is successful and being part of the Bri-Stor Group gives me huge confidence that I can pursue my career here and hopefully continue to gain higher qualifications.”

Gemma has big ambitions at Alpha Manufacturing and she has every reason to be excited about her career. In just four years, having come through the Higher Apprentice route, she is now a fully-qualified Production Engineer with no limits to her capability and career aspirations. This is Gemma’s story, a story that will inspire other students considering an Apprenticeship or Higher Apprenticeship.

When Gemma was at school, she always knew she wanted to get into business and more specifically engineering but wasn’t entirely sure what this path would look like. She certainly didn’t anticipate that just four years into her career and still in her early 20s she’d be running the production engineering for some of Alpha’s most complex jobs. As well as the production side of her role, Gemma has built her confidence and skills to be able to guide and direct many colleagues on the shopfloor, often working in a dynamic and high intensity environment.

Gemma tells us: “If somebody had told me four years ago that I would be a fully-fledged Production Engineer I wouldn’t have believed them. To no longer wear the badge of ‘Trainee’ is just mind-blowing, when I changed my email footer I was just overwhelmed, it’s a tiny thing but it was poignant. I’m not an overly emotional person but all that hard work just felt worth it.

“All the way through school I knew I wanted to get into a job and start my career early but I also wanted to combine it with training and ultimately a higher-level qualification such as a degree so when I learned about Alpha Manufacturing’s Apprenticeship Scheme it ticked all my boxes and more.”

Gemma spent two years at the The JCB Academy combined with her role at Alpha Manufacturing and after completing her foundation degree, Alpha sponsored Gemma to complete her Manufacturing & Production Engineering Degree at Derby University, which she completed in 2020. Gemma tells us more: “Combining my role at Alpha as a Higher Apprentice and furthering my studies at Derby University has worked really well for me. I guess I wanted the best of both worlds – I wanted to start my career and begin earning money but also wanted to gain the skills and education to be able to really advance my career at Alpha. When I say to people “I love sheet metal” I’m sure they think I’m mad, but I really do! I love the fast pace at Alpha too, I’m surrounded by brilliant people who have really helped me nurture my skills. I’ve had to learn very quickly about how to adapt my skills to get the best out of others, but I’ve grown in confidence in a relatively short period and now I can hold my own in most situations.”

For Gemma, her future is bright and she’s excited to see what will come next, she concludes: “Right now, I’m loving my job, every day I come into work with a smile on my face and I look forward to the next challenge. I’m much further ahead in my career than others of the same age and I’m glad I jumped onto the Higher Apprenticeship route – it’s put my career path right on track.”

What’s the best thing about being an Alpha Apprentice? “You learn very quickly, there are so many talented people to guide and support you. There are tough days when you’ve got so much to take in, it can feel overwhelming but then it all just falls into place, you adjust to that very quickly. I love working in the world of manufacturing and engineering – there are limitless opportunities for people that just want to work hard and build a career. This is the place to do it.”

“After my GCSEs I was pretty set on sixth form to be honest, but I felt like I was getting swept along with other students, rather than what I wanted to do”, explains third year Alpha Manufacturing Apprentice, Dan Gill. “All my mates were choosing A ‘Levels and I really wanted to get away from the classroom and start earning a living. The opportunity to get paid to learn really appealed to me so joining an Apprenticeship seemed like the perfect option.”

After finishing his GSCSEs Dan visited a few firms to look at their Apprenticeship Scheme and weighed up all his options, as he explains: “I looked at a few Schemes and immediately dismissed any Scheme that was too classroom-based. I wanted a Scheme that would feel like hands-on work, accepting that I’d also have a lot to learn. When I visited Alpha, I was completely overwhelmed by the world-class machinery and automation of the entire manufacturing process. My dad’s an engineer and I’ve always been fascinated by anything with moving parts – even watches fascinate me, so Alpha completely bowled me over. Another factor that swayed me was meeting our Apprenticeship Manager, Will Davies-Hill, he’s nothing like a teacher but is a really strong mentor and I felt immediately that Alpha was exactly what I was looking for.”

Now in his third year and reflecting on year one and two of the Apprenticeship Scheme, Dan is keen to tell other students considering an Apprenticeship that the Bri-Stor Group approach is way beyond the ‘school’ approach, as he continues: “I looked at the prospectus for Bri-Stor Group and I had many questions about year one at The JCB Academy, to be honest I still had some reservations on day one, but all those were set aside after the first few hours! The teaching is so engaging and it’s so hands-on, it feels like the best DT lesson you’ve ever had, and then you come back into the business and apply all that learning to the real-world, it’s so rewarding.”

Dan is an exemplary Apprentice and has shown grit and determination to succeed from the get-go, with a promising career in Alpha Manufacturing ahead of him, Dan is keen to continue with his education and balance a career, he says: “I love the maintenance rotation and the quality department is pretty cool, I’m learning all the time and because we’re getting such a well-rounded introduction to Alpha Manufacturing it’ll make it much easier to choose my eventual career path.”

Would you recommend the Alpha Manufacturing Apprenticeship Scheme? “If you’re not a fan of the classroom this is the perfect opportunity to really accelerate your career and earn a living at the same time. I made the perfect choice by coming to Alpha and I know I’ve got a bright future ahead.”

After a twenty-year career in the Army, retiring as a Warrant Officer in 2015, Will Davies-Hill was ready for the next chapter in his career. Joining Bri-Stor Systems and securing a position in the electrics team, Will slotted straight into the fast-paced and dynamic culture of the business and was immediately struck by the firm’s attitude towards career progression and personal development, as he explains:

“Having spent two decades of my life in the military I’m well aware of the importance of discipline and personal improvement and these are two values that I recognised in Bri-Stor Group, so when the opportunity came up to advance my own career as the Apprenticeship Manager I jumped at the chance. I’d already observed the fantastic opportunity our Apprentices were being given but I knew, with the right support, I could take the Scheme to the next level.”

Six years on and Will and the wider teams in the Group have developed a fully accredited Apprenticeship Scheme, recruiting approximately 15 students each year to join one of the region’s fastest growing businesses. With strong ties to both engineering and manufacturing disciplines the Bri-Stor Group Apprenticeship Scheme is in high demand, Will continues: “My dedicated role is all about nurturing and developing young talent. We attract applicants from across the county who can see the diverse and exciting nature of our Scheme and I believe that’s because we’ve embedded the real ethos of Apprenticeship into our scheme – giving young people the opportunity to put their ambitions first.

“My own career experience in the military has given me a unique insight into what drives and motivates young people, often in challenging situations, so I have brought this experience to Bri-Stor Group and today, we are delivering what I believe is a solid blend of learning, experience and the opportunity to use initiative and self-discipline. It has to be said though, we know how to have fun and we love the comradery amongst the Apprentices – we give them ample opportunity to let off steam and really bring their personalities to the work place. There is space in this business for everybody, our role is simply to nurture their talent.”

While year one and two of the Scheme are focused on learning and experiencing different roles, in year three, the Apprentices are getting stuck into a role which matches their ambition, talent and the needs of the business. According to Will, this transition can be more challenging for some than others, but Will has this to say: “whether an Apprentice is joining us at 16, 18 or even older, we understand that coming into the work place can be a daunting prospect. In year one we spend a lot of time focusing on business etiquette and expected behaviour – these are essential skills that need to be acquired but we do it in a subtle way and by year two, they’ve seamlessly transitioned from pupil to colleague.”

With the pandemic affecting both education and workplace training for almost every business in the UK, Bri-Stor Group has adapted its Scheme to ensure Apprentices can stay on track, Will comments: “It’s been a challenging time, no question, but we have a robust plan in place to ensure year one Apprentices can continue with the three-year plan. That’s just one of the benefits of joining Bri-Stor Group, our fully accredited Apprenticeship Scheme is highly regarded but our intake numbers enable us to flex as situations beyond our control change. That said, I am incredibly proud of the resilience our Apprentices have shown in the last 12 months – these are incredibly challenging times and it’s testament to their attitude and team-spirit that they all continue to grow and develop their business skills.”

What are you looking for in this year’s Apprentices? “We are in tough times and we are keen to see how applicants have responded to the uncertainty of education through a pandemic. Those that have continued to show determination to succeed will thrive at the Bri-Stor Group.”

Sub contract manufacturing is always a challenging environment, with an ever-changing portfolio of parts that present their own unique hurdles to overcome. The production team must be flexible and dynamic in order to meet demand and deliver consistently. This is “the norm” in a fast-paced manufacturing environment and at Alpha Manufacturing, we have the people in our teams to constantly meet these challenges.

Since March 2020 however, the challenges faced by manufacturing production teams have been amplified as they have had to adapt to situations that could never have been expected 12 months ago due to COVID-19. From the quick adoption of new safe working practices, to the rapidly changing nature of work, to availability of material and indeed, availability of our people. Combine all this with unprecedented demand for COVID safety products and the task becomes a complicated one.

Managing all of these moving parts has been a challenge but as a team, we have managed not only to survive the situation but thrive, acquiring new customers in the process. To date, we have produced close to 10,000 sanitising and cleaning units of different types and 5000 segregation screens, since March 2020. In one project in particular, design, procurement, production and quality all came together to adapt a segregation screen design and put that new design into full production within 72 hours over a weekend in order to meet the customer’s emergency demand.

There are certainly unexpected positive outcomes that we can also take forward from the current situation. For example, the strengthening of existing relationships with customers and suppliers as we have all pulled together and adapted our methods of working. Simple things such as using platforms like Zoom in place of traditional face to face meetings, allow us to be more open and connect in a flexible way. We have also learned that remote working can be done effectively and, in some situations, actually boosts output.

Leading our teams during this period has tested us without a doubt but through strong communication and agile management I feel we’ll actually emerge stronger together. By all pulling in the same direction and adapting to changing situations as they’ve arisen, we’ve built a greater trust and understanding within our business.

ABOUT THE AUTHOR

Neal Lafford has 17 years’ experience in engineering and manufacturing, with a deep understanding of operations and production management. He joined Alpha in 2012 as Business Improvement Manager before becoming Quality Manager. Neal has been Operations Manager for two years and leads Alpha’s Production, Planning, Purchasing, Production Engineering & NPI, Quality and Logistics teams.

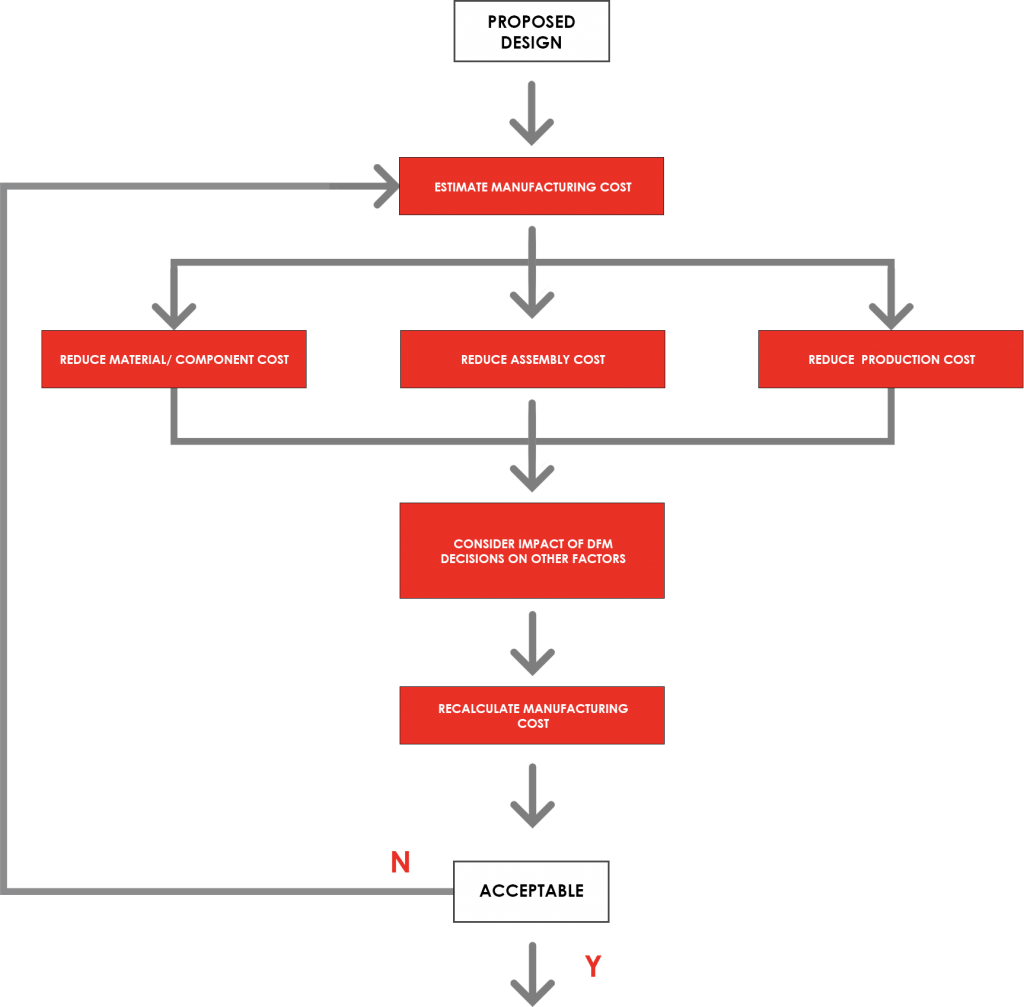

Design for Manufacture (DFM) is a crucial process of optimising a part or product to make it easier, faster, more efficient and cheaper to manufacture. It enables any potential issues with the design to be identified well before manufacturing begins, this is particularly important where parts are to be produced in high volume.

DFM is a holistic approach which looks at the product design in its entirety and follows five key principles:

This involves analysing the current processing methods used to produce the part. DFM teams will ask whether they are the most efficient/ cost effective processes. Sometimes parts are over processed, resulting in an unnecessary cost for the customer and DFM will aim to minimise secondary processing. For example, a part may be laser cut and then punched. By using a Punch/ Laser combination machine these two processes can be combined, reducing cost and opportunities for error.

The original manufacturing drawings are inspected and analysed to check that they conform to good manufacturing principles. Unnecessary specifications or high tolerances can be removed or adjusted to reduce processing and cost and material choice is reviewed. Where the same result can be achieved with different specifications, DFM will aim to suggest this change.

The material choice of the product is investigated and designers will ask themselves whether there is a more effective alternative. They will look at the application of the finished product and assess material requirements such as:

· Physical properties – Does the material need to be strong/ light/ malleable/ durable?

· Visual properties – Does the material needs a certain finish such as mirrored or brushed?

· Thermal properties – Does the material need to resist or conduct heat?

· Colour – What colour does the part need to be, are there other standard colour options?

· Electrical properties – Does the part need to conduct or insulate against electricity?

· Flammability – How flame resistant does the part need to be?

Where is the finished product likely to be located and does this require any particular materials, finish, properties or features. An example of this could be a powder coated product which is used in a harsh outdoor environment, such as street furniture in a coastal location. A high salt spray protection rating is required to increase durability.

DFM will assess whether there are any regulations or restrictions to consider in the design. Some sectors such as medical or automotive will require a much higher level of testing and compliance than others.

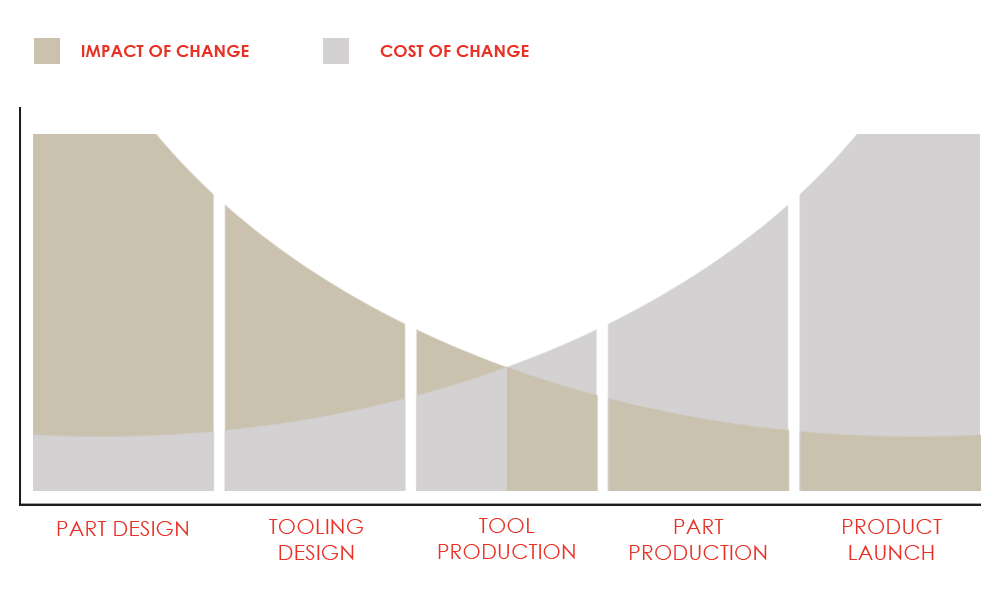

The Design for Manufacture process is most effective early in the product life cycle as the cost of design change is significantly lower and changes are easier to implement at this stage than later on, as shown below:

Where a product design already exists, the Design for Manufacture process aims to challenge the original concept in order to identify any areas for optimisation. This involves a deep review of the product in every aspect including manufacturing drawings, material choice, processing method and any tooling involved. In sub-contract manufacturing, this would then involve suggesting any changes to the customers.

Here at Alpha, our design and engineering teams collaborate with every customer to optimise their product design for manufacture. Whether it is a new product requiring design input from the outset, or an existing design which we can review and suggest changes.

If you’d like to discuss how Alpha can reduce costs for you by optimising your product deign for manufacture, get in touch with one of our sales engineers today.

The products, which are an evolution of the sanitiser units manufactured by Alpha for a POS supplier in recent months, combine sanitiser dispenser, paper towel unit and waste bin into one convenient hygiene station. Manufactured primarily from 1.2mm steel, finished in the brand colour of ultra-marine blue and fully decaled, they offer a durable, smart looking hygiene solution for supermarkets.

Alpha’s customer, a leading merchandise and Point of Sale supplier, originally got in touch in the summer of 2020 amid the first UK lockdown as demand for COVID-19 protection products surged. The initial order saw Alpha produce 3500 hand sanitisers predominantly for the leisure and hospitality sector as the UK Government planned its re-opening of UK pubs and restaurants. Alpha quickly stepped-up operations to meet the unprecedented demand and at peak production, 450 units per day were rolling off the production line.

Since then, Alpha’s relationship with the customer has developed as demand for COVID protection products has remained high, with organisations from all sectors taking action to make themselves COVID-secure. With retail brands now looking for more permanent, functional hygiene solutions for their store entries, this new unit will start to be distributed across the UK, helping shoppers stay safe.

With the first samples now signed off by the customer, Alpha’s assembly teams are ramping up production and will be completing 100+ units each day, with thousands required in total. Be sure to make use of them as they appear in your local supermarket in the coming weeks and stay safe.

Thanks to robust protection measures implemented during the first lockdown and further tightened during the subsequent months, Alpha and sister company Bri-Stor Systems are able to safely offer an uninterrupted service to existing and new customers. Where possible, employees are operating from home while those still on site are safely distanced and working to strict COVID-19 guidelines.

During the first UK lockdown, Alpha initially reduced its manufacturing operations to a skeleton staff to ensure that supply of parts to healthcare customers and those associated with the NHS remained unaffected. As the situation developed, a spike in demand for various COVID-19 prevention products such as partition screens and sanitisation stations meant that operations were upscaled with new, effective safety guidelines implemented across the business.

Thanks to these measures, combined with high levels of factory automation due to continued investment, Alpha are now able to quickly adapt to sudden changes in national restrictions with no loss of service level. The sales team are available to discuss any new customer requirements, with design and engineering teams also on hand to offer advice and support.

Natalie joined from nearby Central Fasteners, based just around the corner from Alpha on Hixon Airfield industrial estate where she had worked for 12 months in a primarily purchasing which also incorporated some telesales responsibilities.

Natalie’s new role will see her take responsibility for order processing, invoice queries, purchasing and order chasing. With business at Alpha now back to normal levels, the purchasing department is as busy as ever with manufacturing materials and stock in constant high demand to fulfill new orders. Natalie will be an important link between production and purchasing, expediting orders and ensuring a smooth purchasing function.

On her experience of Alpha in her first few weeks, Natalie said:

“I knew about Alpha and Bri-Stor Systems as they’re in Hixon, near my old workplace and we had supplied them in the past. The biggest difference here is that it’s quite a lot bigger than my last place. Manufacturing is also a new industry for me so there’s lots to learn, it’s quite exciting. The whole team here has been really friendly and helpful, making it easy to settle in and learn my role.”

Outside of work Natalie is active, attending the gym regularly to keep fit and is a keen walker. While at home she enjoys relaxing of an evening with a book. A bubbly and sociable person, Natalie has quickly settled into the Alpha team is already proving to be an important member of the purchasing team. From all at Alpha, welcome aboard Natalie and good luck in your new role.