In 2016 I joined Alpha as an Apprentice because I knew I was interested in Engineering, although I had no idea of what role I’d like to work in. As part of the Apprenticeship rotation programme, I worked in the maintenance department and it instantly felt like a good fit. So, once I completed the course, I asked to join the team full time and I’ve now been here for two years.

The Maintenance team deal with such a wide variety of issues every single day, from machine breakdowns and maintenance to site electrics, new installations, groundworks, painting, and much more. We’re on call-out for any breakdowns and issues outside of normal working hours so we have to be flexible. Currently there are 8 of us working in the maintenance team, including 2 electricians and we’re all relatively young and ambitious.

If a machine is out of operation it can have serious implications for the business because we work to a busy schedule with tight deadlines. If one customer’s parts are delayed because of machine downtime, it has a knock-on effect for other parts and other customers. This is why it’s so important to have an effective, dynamic maintenance team to rely on. We often have to work quickly under pressure to make sure downtime is minimised. That might mean working unusual hours or going the extra mile to make sure a machine part is here for a certain time.

The reason I love working in the maintenance team is that we’re a bit like the unsung heroes in manufacturing. We work constantly in the background to make sure everything is running smoothly. If no one notices anything wrong, it means we’ve done our job right. Personally, I’m aiming to become Alpha’s Maintenance Manager, so I take every day and every new challenge as an opportunity to learn something new.

|

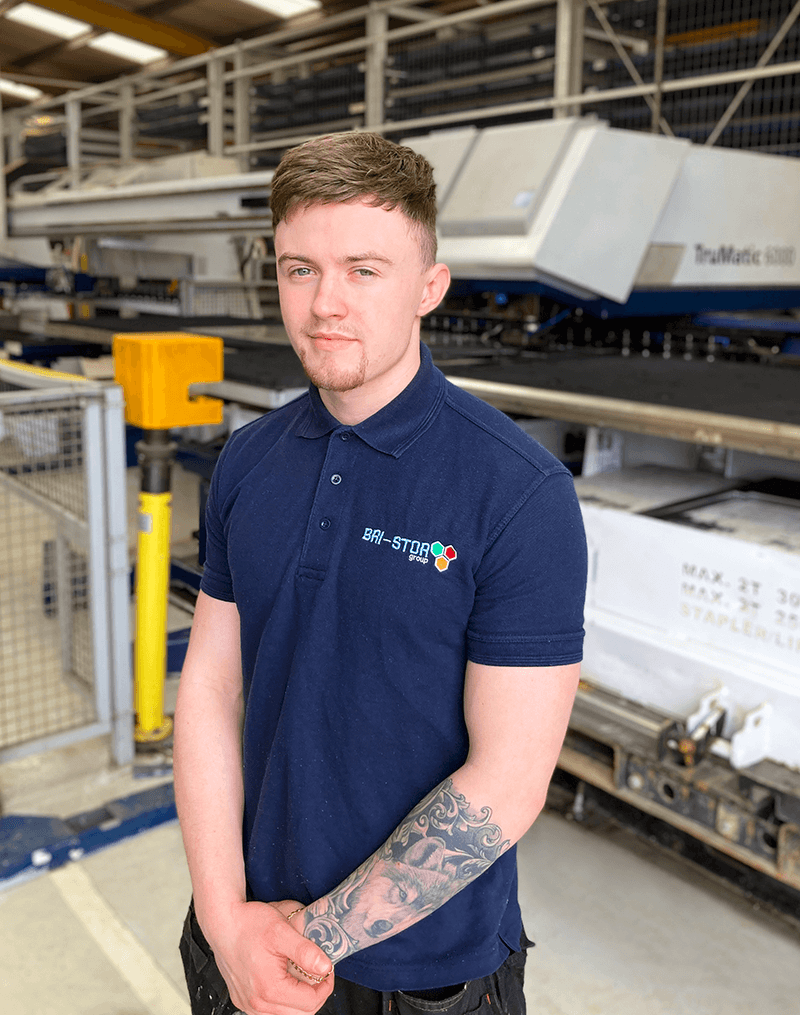

ABOUT THE AUTHOROwen Jones joined Alpha as an Apprentice back in 2016 after hearing about the company from friends in his home village of Hixon. One of his proudest memories during his apprenticeship came during the annual team building trip to Elan Valley in Wales, where he was chosen as project lead in a group community project. He still credits this experience for the gains in confidence that ultimately helped him succeed as an Apprentice. Today, Owen is a vital member of Alpha’s Maintenance team, with the ambitions of one day becoming Maintenance Manager. |