As part of the Bri-stor Group’s push to reduce our environmental impact, Alpha Manufacturing, Atlas Coating and Bri-Stor Systems have changed the way we process our waste.

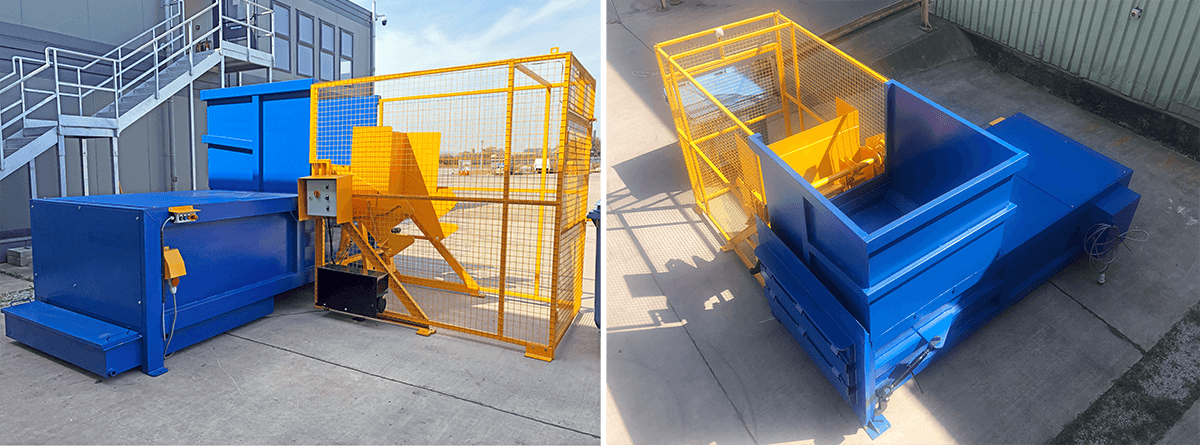

The Group recently invested in a new waste compactor into which all non-recyclable waste produced on-site is placed. This replaces the many skips that were previously located around each of the businesses, which were collected twice a week and transported to landfill sites.

Instead, the compactor waste is collected just once every two weeks and its contents converted into refuse derived fuel that can be used in place of traditional fossil fuels to produce energy. This now means that 100% of the Bri-Stor Group’s non-recyclable waste has been diverted away from landfill, while carbon dioxide emissions from waste collections has been reduced by 75%. That’s equivalent to taking 34 cars off the road in a year or planting 316 trees.

This is just one of the many steps currently being taken by Alpha Manufacturing, Bri-Stor and Atlas to minimiSe our carbon footprint across all aspects of our business.