Assembly and integration of sheet metal products is an increasingly vital part of the company as demand increases. We spoke to Rob Eley, Alpha Commercial Director to discuss why this service has increased in popularity, and how Alpha Manufacturing has responded to the new demand.

Complex assembly is an increasingly popular service in numerous industries. Why do you think that is?

Rob: We have definitely seen an increase in demand for fully assembled finished products to fine tolerances and finishes. Many of these have been modular solutions designed by our customers which reduce installation or assembly by their end-user customers.

This allows our customers to offer a complete all in one solution, which seems to be an increasing trend, particularly in the construction sector. By offering a pre-assembled modular solution through offsite manufacturing, the need for additional trades such as plumbers or electricians on site is reduced, which in turn, results in cost savings for the end-user.

How is Alpha’s flexible approach different from other manufacturers?

Rob: Alpha takes a project basis approach to new clients. We can offer the entire sheet metal fabrication service but if something might be slightly outside of our capabilities, or if it is new to us, we will assess whether it would be viable for us and the customer to undertake the work. We’re not shy about investing in and developing new processes where required.

Alpha’s traditional business model depends on high volume and repeat requirements of products. Offsite manufacturing demands more tailored solutions, so we have adapted to become more flexible. We have done this for various new customers in recent times, which has seen our facilities evolve and our business enter new markets as a result. This flexible approach allows us to be open-minded when considering new business.

What added value does Alpha offer to customers?

Rob: Alpha is able to offer the entire sheet metal fabrication solution. All processes are carried out on our premises, reducing cost in outsourcing and in turn, the transport required. We have the skills, equipment and engineering knowledge to take a project from design, all the way through to final assembly and finishing.

In addition, our drive towards factory automation further reduces cost for the customer as we are able to reduce waste and cost throughout processing. Value engineering is also a vital part of what we offer.

What is the benefit of carrying out value engineering before manufacture?

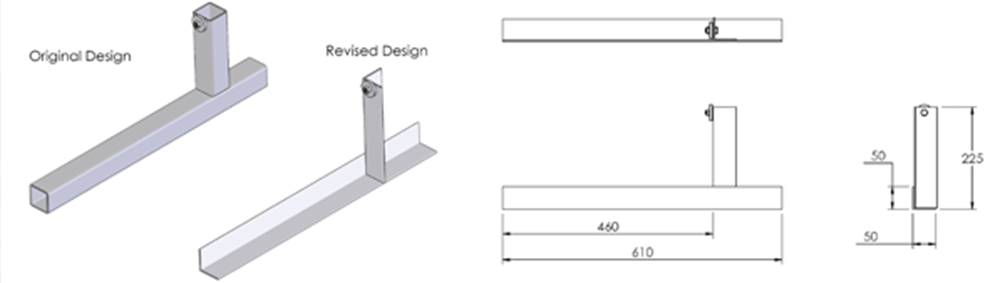

Rob: Value engineering is crucial for our customers in reducing the cost of manufacture. We can suggest alterations to a part or the assembly process to reduce material usage or to remove unnecessary processing time. Where possible, we will suggest new processes which are faster or less expensive to achieve the same end result. This gives our customers the peace of mind that they are getting the best value for money in their manufactured products.

How do you use CAD/CAM prior to assembly? Why?

Rob: Alpha has a dedicated design team who will work with customers from the outset to refine an existing design. This allows us to design for manufacture, making sure that the constituent part or assembly is best optimised for our manufacturing procedure by using CAM systems.

We can reduce or completely remove the need for some processes by redesigning or adjusting parts in this way. All parts can be fully modelled in 3D CAD software to guarantee their dimensional accuracy. Where many components are put together into an assembly, CAD software allows designers to simulate the assembly and ensure that the final manufactured parts fit together as designed.

Why is accuracy so vital in assembly? What can go wrong?

Rob: All of Alpha’s customers will have specified tolerances for the parts that they require, of varying accuracy. Some sectors, such as automotive or aerospace, will have very fine tolerances as their parts are often high performance or safety-critical, whereas other customers don’t require such stringent tolerances. Where many sub-components are manufactured to create one larger final assembly, accuracy in all components is crucial to ensure that the final product fits together correctly.

Is there any limit to the size or complexity of project Alpha can take on?

Rob: Alpha will always assess this on a project basis and have taken on assembly projects much bigger than anything handled previously. However, we would potentially become limited by storage space without having to acquire new premises. Also, maneuvering large components or assemblies would become an issue where heavy-duty lifting equipment is required.

What are some of the most common projects Alpha takes on?

Rob: Alpha works on projects from a huge range of sectors. Where assembly is concerned, our most recent projects have come from the construction sector where customers have modular solutions designed to fit straight into new builds. These are complex in the manufacturing and assembly stage, which in turn reduces the complexity and ultimately cost, at the installation stage.

What are some of the more unique projects Alpha has undertaken?

Rob: Alpha was approached by a supplier of interactive touch screen gaming machines who required a large volume of finished products delivering to high street betting shops, within a short timeframe. Alpha quickly upscaled the assembly teams with new staff and created a dedicated assembly area including several parallel production lines. Once complete, all machines were delivered to the end-user.

Why is finish quality so important to Alpha?

Rob: Alpha measures its performance on quality metrics which is a key factor for any customer looking for a sheet metal fabricator. Rejected or faulty parts can disrupt supply for customers if they have to be reworked or re-made.

Quality is crucial in Alpha’s reputation and ability to win new business. In terms of assembled products, many of the current portfolio are supplied directly to end-users in e ither residential, commercial or retail environments where a high finish standard is expected.