Alpha Manufacturing offers a broad range of sheet metal fabrication services that provide exceptional results. Our products go through a variety of processes and from design to delivery, we are able to provide quality, efficiency and accuracy.

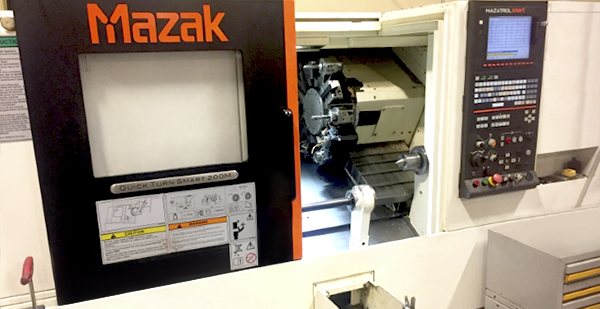

State-of-the-art machining centres allow Alpha Manufacturing to produce the highest quality CNC turned parts for new and existing customers. In addition, Alpha is able to design and manufacture in-house tooling to enable quick turnaround on turned parts for all customer requirements.