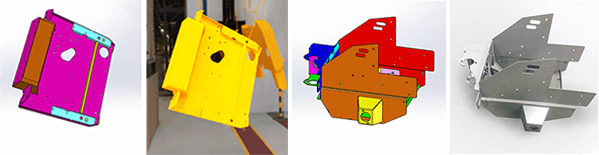

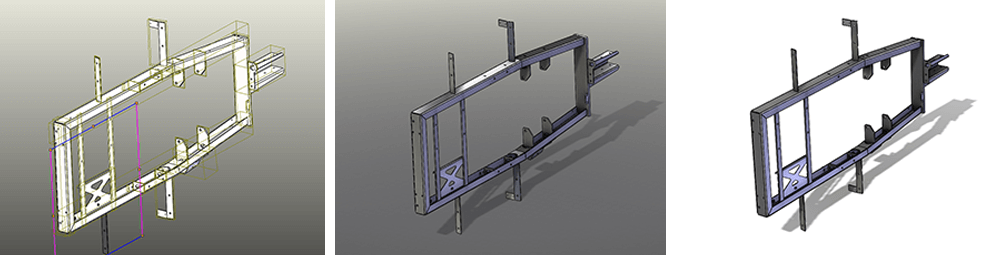

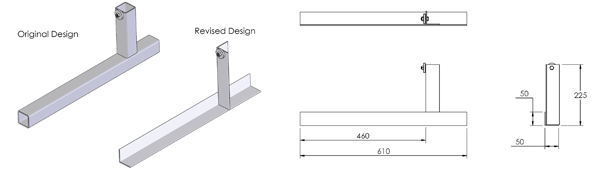

Our expert in house design team works closely with customers from the beginning of each project to ensure that all assemblies are consistently successful at the prototyping stage.

We employ New Product Introduction (NPI) staff to ensure that the metal parts meet our customers’ expectations in terms of specification and quality.

New developments are optimised by our dedicated team to ensure that they utilise the very best in machine and tooling technology. This allows us to offer maximum efficiency whilst maintaining the highest levels of quality for our customers.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.